Carburizing furnace for metal components

Brand SOLO

Product origin CHINA

Delivery time 120

Supply capacity 100

application for accurate carburizing, nitriding and other heat treatment processes under protective atmosphere such as annealing, hardenling, tempering, martempering; austempering;

Increase accuracy for homogeneous treatments

Reduce distortion of the parts for more profitable production

Reduce heat treatment time for higher productivity

for industries including aerospace, automobile, military, machinery, etc..

Download

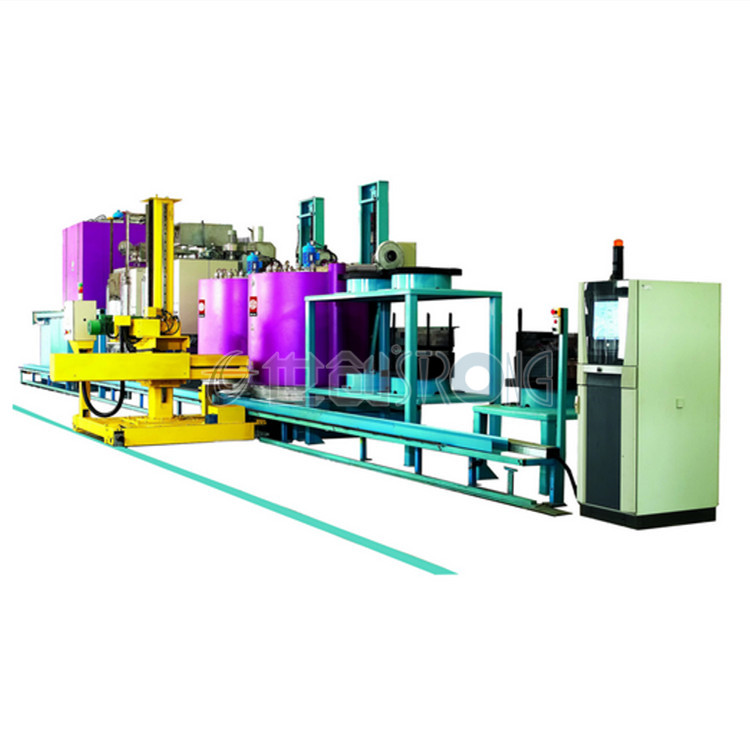

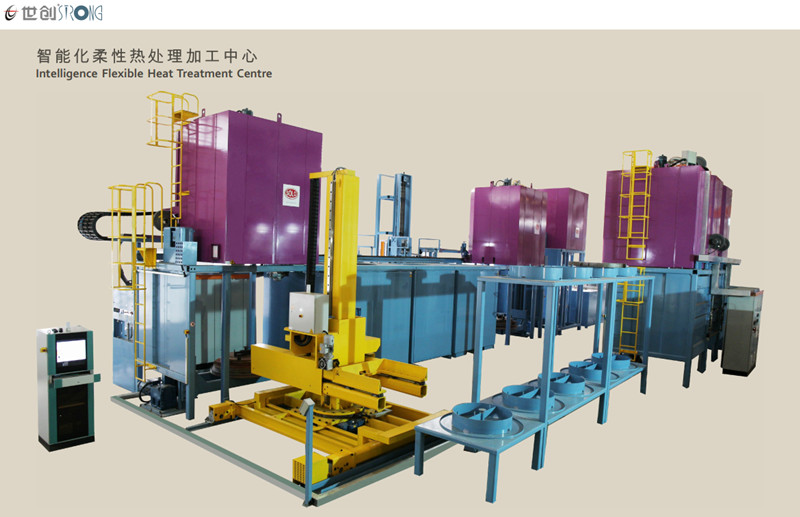

Intelligent Flexible Hardening and carburizing furnace line

This processing cneter is for accurately carburizing, carbonitriding with presicion computer control system for high quality management. This drop bottom bell type furnace is the best choice for heat treatment for high quality demanding industries such as aerospace, automobile, military, machinery, etc.. Various heat treatment processes such as quenching, annealing, tempering, carburizing, carbonitriding, nitriding, nitrocarburizing, oxygen and nitriding, can be realized with controlled atmosphere protection.

Since 1989, Strong Metal have been researching and developing new technology on control atmosphere heat treatment, BELL-TYPE FURNACE and the relevent process is an innovative product, it can resolve lots of challenges which other furnaces encounter.

This bell-type furnace consists of the following four parts: treatment furnace, quench tanks, control system( electron and gas) and malupulate.

Strong Metal Develops various heat treating solutions for different industries. Strong Metal provide other energy solutions including gas, oil and electricity. Strong Metal recommends you to consider your environmental protection process also, any energy conservation, gas purification or resource recycling issues, please consult us. Hope we can help you and join hands together to restore a purified Green Earth! Heat treatment Center, Flexible Heat treatment Center, Intelligent heat treatment.

Intelligent Flexible Heat Treatment Center application for annealing, hardening, tempering, carburizing, carbonitriding, nitriding

Intelligent Flexible Heat Treatment Center

Applications:

Carburizing, carbonitriding, nitriding, nitrocarburizing high presicion and quality parts for aerospace, automobile, machinery and other industries.

Features:

Oxidation free at the surface to get high quality.

Effecient insulation sleeve for reducing production cost no loading density limitation for increasing productivity

Maximize mechnical performance while reducing distortion

Multiple quenching media options: salt., polymer , water, and high gas pressure(max.15 bar).

Heat treatment Center, Flexible Heat treatment Center, Intelligent heat treatment.

Description:

Advanced computer control management system, the latest SIEMENS/Microsoft industrial hardware and software standards, with man-machine interface in Chinese and English, animation display of working conditions, and a closed loop full loop through hydrogen analyzer, mass flow meter, solenoid valve, etc. Automatic nitrogen potential control; computer cabinet with air conditioning, easy to operate, safe and reliable.

Environmentally-friendly tail gas treatment technology, adopts tail gas treatment system with catalytic cracking device, uses liquefied petroleum gas (LPG) to support combustion, so that the residual ammonia gas becomes 25% nitrogen (N2) and 75% hydrogen (H2), and then The exhaust gas is ignited by the heated resistance wire, and the exhaust gas is environmentally friendly. There is a safety device to ensure that the ammonia gas entering the furnace is closed when the exhaust gas is accidentally extinguished; it protects the health of the operator and the safety of the surrounding environment.

A brief introduction of Strong Metal

Guangdong Strong Metal Technology Co., Ltd.(StrongMetal) is public listed high tech company which is committed to develop and manufacture advanced heat treating equipment and provide customized heat treatment engineering for various industries including aerospace, steel, machinery, tool, automobile, electronics, home appliaces, contruction, ect.

Guangdong Strong Metal Technology Co., Ltd.(StrongMetal) is public listed high tech company which is committed to develop and manufacture advanced heat treating equipment and provide customized heat treatment engineering for various industries including aerospace, steel, machinery, tool, automobile, electronics, home appliaces, contruction, ect.

Strong Metal Expertise covers comprehesive heat treatment processes such annealing, hardening, normalizing, tempering, carburizing, nitriding, carbonitriding, nitrocarburizing, ion plating ...

StrongMetal Equipment Manufacturing includes: Continuous vertical bright annealing line(BAL) for stainless steel strips;Continuous horinzontal bright annealing line(BAL) for stainless steel strips;Continuous pickling and annealing line(PAL) for steel strips;Mesh belt conveyor furnace for heat treating metal parts;Intelligent flexible heat treatment center;Horizontal hardening and tempering line;Bell-type furnace line;Bell-type nitridding furnace;Pit type carburizing furnace; Pit type vacuum impulse nitriding furnace;Bell-type vacuum cleaner..

Our advantages

Experience

Strong Metal has over 30 years’experience in heat treatment and has accumilated abundant know-how techniques which bring values to our customers.

Innovation

Strong Metal keeps continuous cooperation with high level universities and global companies for R&D on heat treatment technology which keep our customers’businesses forward-looking and competitive

Quality

Strong Metal ISO9001 quality management system employs strict control on equipment and materials provided by strong metal.

Team

Strong Metal is multi-disciplined team engaging in within 24 hours responsive global services for heat treatment equipment design, manufacturing, engineering, erection, commission, training.

Who we serve

Strong Metal provides various heating solutions for industries including steel industry, machinery, aerospace, automobile, arms, tool, home appliances, building, electronics, electrical.

Strong Metal enjoys great honor for serving customers some of which are the leaders in their industries, just name a few below:Heat treatment Center, Flexible Heat treatment Center, Intelligent heat treatment.