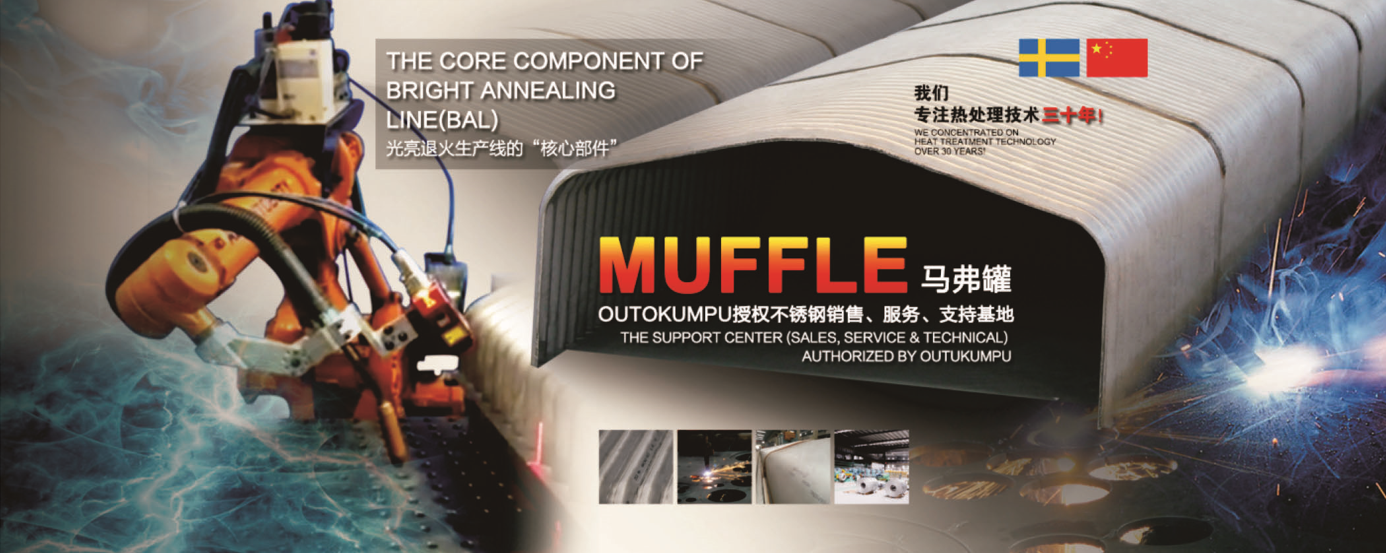

- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

2021 Mysteel Nickel, Chromium, Stainless Steel and New Energy Annual Conference was successfully held

At the beginning of December 2020, the 2021 Mysteel Nickel, Chromium, Stainless Steel and New Energy Annual Conference hosted by Shanghai Ganglian Information Technology Co., Ltd. was grandly held in Wuxi. The exhibition mainly focuses on the development direction of the industry, and provides a detailed interpretation of the consumption areas of the stainless steel industry, providing a platform for companies in the industry to discuss hot topics such as international forms and innovation and transformation in the stainless steel, nickel and chromium industries.

At the meeting, Liao Zhiyan, general manager of Foshan STRONG METAL Materials Co., Ltd., gave a special report on the analysis of the market situation of stainless steel cold-rolled strip, expounding the development process of the stainless steel cold-rolled The strip application analysis is briefly analyzed, and the cold-rolled pickling annealing and bright annealing are compared.

Liao Zhiyan, General Manager of Foshan Strong Material Co., Ltd.

Liao Zhiyan, General Manager of Foshan Strong Material Co., Ltd.

At the same time, several models of Strong Metal's equipment with the characteristics of wide width and large production capacity were introduced. They are:

It can produce a vertical bright annealing furnace with a belt thickness of 0.05-1.0mm, a width of 1250mm, a maximum capacity of 350 tons/day, and a gas-based heating method.

It can produce a horizontal looper bright annealing furnace with a belt thickness of 0.3-2.0mm, a width of 1250mm, a maximum capacity of 350 tons/day, and a gas-based heating method.

It has the characteristics of energy saving and low consumption, and the overall technology has reached the international leading level.

Vertical bright annealing furnace with wide width and high production capacity

Vertical bright annealing furnace with wide width and high production capacity

Vertical bright annealing furnace with wide width and high production capacity

Horizontal bright annealing furnace with wide width and high production capacity

Horizontal bright annealing furnace with wide width and high production capacity

The equipment with narrow width, small capacity and multiple specifications are:

It can produce a horizontal bright annealing furnace with a belt thickness of 0.1-2.0mm, a belt width of 850mm, and a maximum production capacity of 100 tons per day. The heating method is mainly electricity, natural gas, and gas;

It can produce a vertical looper precision annealing furnace with a belt thickness of 0.1-2.0mm, a belt width of 400-1300mm, and a maximum production capacity of 100 tons/day. The heating method is mainly electricity, natural gas, fuel oil, and gas.

And horizontal strip stress relief furnace and strip degreasing production line.

horizontal bright annealing furnace

horizontal bright annealing furnace with vertical loopers

horizontal bright annealing furnace with vertical loopers

hhorizontal bright annealing furnace

hhorizontal bright annealing furnace

CContinous degreasing line for stainles steel strips

CContinous degreasing line for stainles steel strips

The most important core component is the furnace bladder-a composite corrugated muffle tank. The high-temperature alloy furnace liner we use is 3~5 times longer than the ordinary 310 furnace liner, which greatly saves the cost of use. The ultra-wide 1600MM alloy furnace liner produced can support the annealing of high-end precision stainless steel strips to ensure product quality. Purchasing high-end alloy steel plates to ensure service life and indirect cost savings.

Manager Liao also clearly pointed out that the current economic globalization is facing a countercurrent, and the epidemic has a wide-ranging and far-reaching impact. The traditional international economic cycle is significantly weakened or even blocked. Foreign purchases are more likely to be affected by the epidemic, unable to deliver on time, and vulnerable to force majeure. In this case, strengthening the domestic economic cycle will help strengthen the resilience of economic development. It will also help drive the international economic cycle and realize the mutual promotion of domestic and international cycles.