-

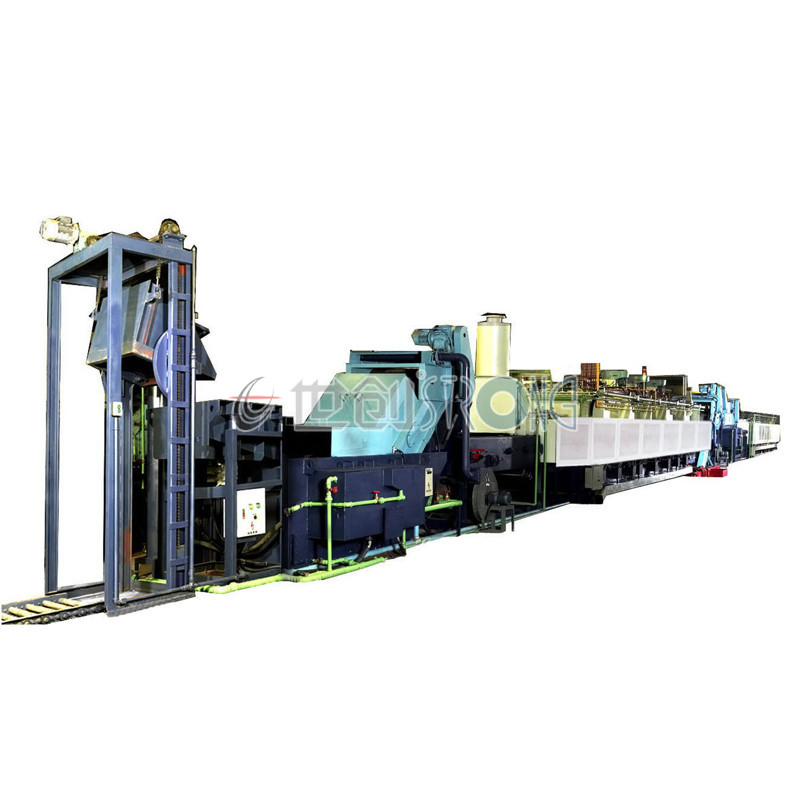

Conveyor Mesh Belt Hardening and Tempering Furnace Line

Intelligent heat treatment production line of mesh belt furnace is suitable for mass production of various small workpieces,such as carburizing, carbonitriding, quenching, oil quenching, water quenching and other heat treatment processes, processing screws, nuts, stamping parts, etc.

Send Email Details -

Conveyor furnace for carburizing, hardeing and tempering

1)Carburizing, Carbonitriding; 2)quencing under controlled atmosphere; austempering; 3) oil queching, water quenching.

Send Email Details -

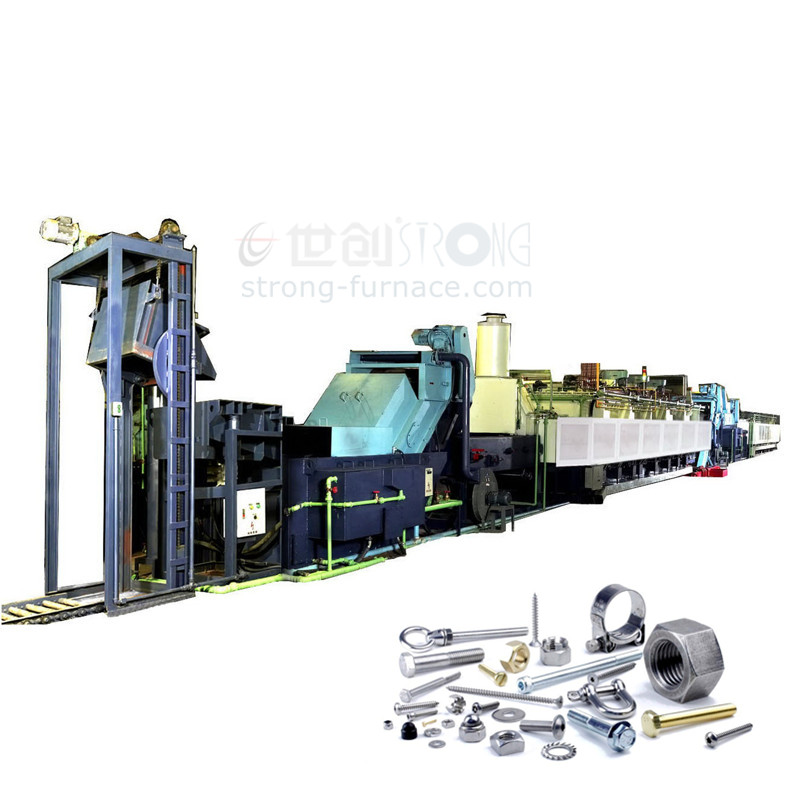

Continuous heat treatment furnaces for heat treating fastners bolts nuts screws

Continuous heat treatment furnaces for heat treating fastners bolts nuts screws 1)Carburizing, Carbonitriding; 2)quencing under controlled atmosphere; austempering; 3) oil queching, water quenching.

Send Email Details -

Conveyor type continuous annealing furnace for parts

This conveyor furnace line is used for heat treatment of various precision electrical materials, brazing and stainless steel heat treatment, solution treatment, powder metallurgy sintering and bright annealing of metal parts, etc.

Send Email Details -

High Temperature Precision Conveyor Furnace Line

This conveyor furnace line is used for heat treatment of various precision electrical materials, brazing and stainless steel heat treatment, solution treatment, powder metallurgy sintering and bright annealing of metal parts, etc.

Send Email Details -

patta patti bright annealing line for india market

Bright annealing line(also called bright annealing furnace) for annealing patta/patti stainless steel sheet under protective atmosphere. It is subsitute process to annealing & pickling process which raises enviroment issues in stainless steel processing industry in india.

bright annealing line annealing furnace for patta stainless bright annealing line for patti stainlessSend Email Details -

Continuous bright annealing furnace for coins

Continuous bright annealing furnace is a conveyor furnace for annealing metal coins. Coins continuously are passing through atmosphere controlled heating and cooling tunnel furnace. No oxidization happens on the surface of the treated coins.

Send Email Details