-

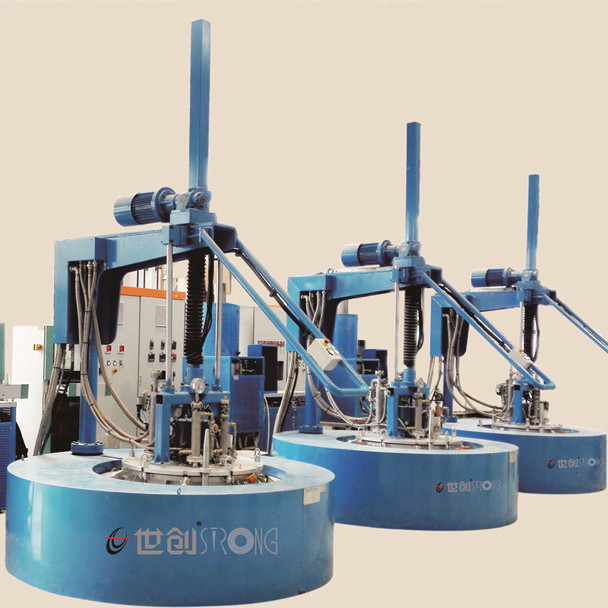

Intelligent Flexible Heat Treatment Center

A comination of smart robot trolley and multiple bell furnaces for flexible application of various heat treatments of quenching, annealing, tempering, carburizing, carbonitriding, nitriding, nitrocaburing etc. under controlled atmosphere.

Send Email Details -

Vacuum Furnace For Metal Heat Treatment

Vacuum quenching and vacuum tempering of tool and die steel; solid solution and annealing of stainless steel and titanium alloy; strengthening treatment of high-speed steel; powder steel sintering; vacuum stress relief annealing of tool and die, etc.

Send Email Details -

-

Heat treatment equipment for heat treating gears

This bell type furnace line adopting modular building block design, suitable for various processes and mass production requirements for under protective atmosphere annealing, tempering, queching, carburizing, carbonitriding, nitriding, ect. Heat treatment equipment for heat treating gears

Send Email Details -

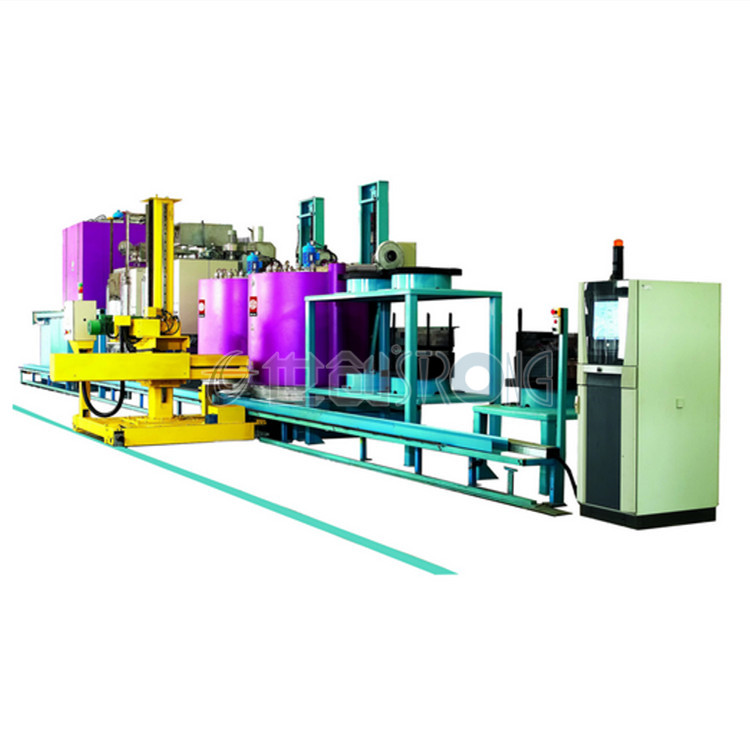

Bell Type Furnace Line

This bell type furnace line adopting modular building block design, suitable for various processes and mass production requirements for under protective atmosphere annealing, tempering, queching, carburizing, carbonitriding, nitriding, ect.

Send Email Details -

Precision Controlled Atmosphere Vacuum Impulse Pit Nitriding Furnace

Precision Controlled Atmosphere Vacuum Impulse Pit Nitriding Furnace.

Send Email Details -

Bell Type Heat Treatment Furnace

This bell type furnace features high quality carburizing without intergranular oxidation, sheet carburizing, ultra-thin sheet carburizing and carbonitriding, less distortion carburizing and quenching, instead of the salt bath furnace heating to reduce the environment pollution, and the flexible organization to meet the application of different industries.

Send Email Details -

Precision Controlled Atmosphere Pit Carburizing Furnace

The industiral furnace is for Precision Controlled Atmosphere Pit Carburizing.

Send Email Details -

Forklift AGV-STRONG unmanned forklift

STRONG intelligent unmanned vehicle adopts the self-developed laser scanning mapping + SLAM algorithm positioning navigation technology to realize the accurate positioning (positioning accuracy ± 10mm) and flexible planning of unmanned vehicles. Compared with magnetic conductivity technology, there is no need to lay a large number of magnetic strips and positioning points on site, the route planning and setting is simple, the maintenance cost is low, and the operation is more reliable.

Send Email Details -

Carburizing furnace for metal components

application for accurate carburizing, nitriding and other heat treatment processes under protective atmosphere such as annealing, hardenling, tempering, martempering; austempering; Increase accuracy for homogeneous treatments Reduce distortion of the parts for more profitable production Reduce heat treatment time for higher productivity for industries including aerospace, automobile, military, machinery, etc..

Send Email Details -

SOLO Intelligent Flexible Heat Treatment Center

application for accurate carburizing, nitriding and other heat treatment processes under protective atmosphere such as annealing, hardenling, tempering, martempering; austempering; Increase accuracy for homogeneous treatments Reduce distortion of the parts for more profitable production Reduce heat treatment time for higher productivity for industries including aerospace, automobile, military, machinery, etc..

Send Email Details -

Precision controllable atmosphere vacuum pulse pit type nitriding furnace

Advantages: Pit furnaces are suitable for long shafts and other workpieces. From simple independent heat treatment furnaces to the most complex fully automated systems, accurate data analysis plays a solid role in the traceability and stability of enterprise products. Vacuum pulse ion nitriding is a new technology. Compared with traditional ion nitriding, it has many advantages. First, pulse ion nitriding has the characteristics of individual control of physical parameters, independent adjustment of process parameters, and a wide range of changes; because of the pulse power supply to arc discharge The inhibitory effect of, so there is no need to plug holes for many parts, high-quality surfaces can be obtained, and no burns; it can improve the depth of the layer, save energy, and improve the utilization rate of the equipment; it can realize ions in deep holes, narrow slits, and micropores. Nitriding.

Send Email Details