-

Intelligent Flexible Heat Treatment Center

A comination of smart robot trolley and multiple bell furnaces for flexible application of various heat treatments of quenching, annealing, tempering, carburizing, carbonitriding, nitriding, nitrocaburing etc. under controlled atmosphere.

Send Email Details -

Heat treatment equipment for heat treating gears

This bell type furnace line adopting modular building block design, suitable for various processes and mass production requirements for under protective atmosphere annealing, tempering, queching, carburizing, carbonitriding, nitriding, ect. Heat treatment equipment for heat treating gears

Send Email Details -

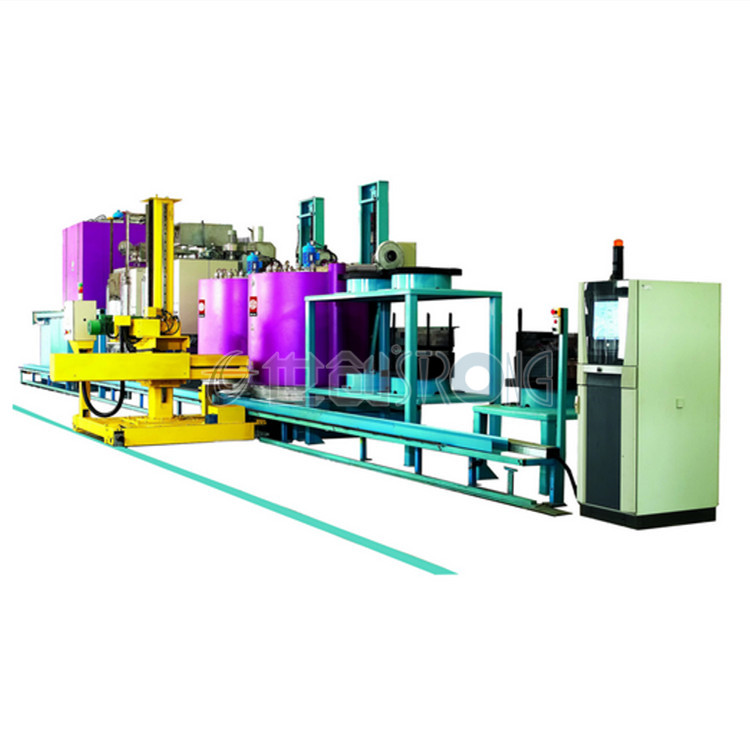

Bell Type Furnace Line

This bell type furnace line adopting modular building block design, suitable for various processes and mass production requirements for under protective atmosphere annealing, tempering, queching, carburizing, carbonitriding, nitriding, ect.

Send Email Details -

Bell Type Heat Treatment Furnace

This bell type furnace features high quality carburizing without intergranular oxidation, sheet carburizing, ultra-thin sheet carburizing and carbonitriding, less distortion carburizing and quenching, instead of the salt bath furnace heating to reduce the environment pollution, and the flexible organization to meet the application of different industries.

Send Email Details -

Carburizing furnace for metal components

application for accurate carburizing, nitriding and other heat treatment processes under protective atmosphere such as annealing, hardenling, tempering, martempering; austempering; Increase accuracy for homogeneous treatments Reduce distortion of the parts for more profitable production Reduce heat treatment time for higher productivity for industries including aerospace, automobile, military, machinery, etc..

Send Email Details -

SOLO Intelligent Flexible Heat Treatment Center

application for accurate carburizing, nitriding and other heat treatment processes under protective atmosphere such as annealing, hardenling, tempering, martempering; austempering; Increase accuracy for homogeneous treatments Reduce distortion of the parts for more profitable production Reduce heat treatment time for higher productivity for industries including aerospace, automobile, military, machinery, etc..

Send Email Details -

SOLO Infiltration furnace production line

Equipment composition of the metal infiltration furnace production line: This heat treatment production line consists of 2 bottom-loading vertical multi-purpose furnaces (1100°C), 1 argon cold tank (ArB), 1 supporting loading and unloading trolley, charging table, electrical control system, It is composed of gas control system, computer control management system and circulating water cooling device.

Send Email Details