Characteristics of roller type mesh belt furnace

Summarize the dozens of characteristics of idler type mesh belt furnace for everyone!

1. The preheating chamber is added at the feeding end of the equipment, which effectively uses the heat energy of the returned mesh belt to preheat the parts into the furnace, which not only reduces the energy consumption but also improves the life of the mesh belt.

2. synchronous rotation of the transmission roller, small mesh belt tension, stable operation, long service life.

3. the furnace is equipped with a strong stirring fan to ensure that the atmosphere in the furnace is more stable and uniform, and improve the consistency of the product after treatment.

4. the heating radiation tube is distributed above and below the furnace and inserted horizontally to ensure uniform temperature, convenient maintenance and replacement.

5. quenching furnace heating each area has a set of independent temperature control system and a set of independent monitoring system to avoid temperature measurement elements aging (damage) and furnace temperature deviation.

6. roller bearing for special high temperature + extra high temperature grease, simple structure, reliable operation.

7. The equipment is equipped with oxygen probe and carbon control meter, which can automatically control the CO% concentration in the furnace according to the process requirements to ensure the product quality after heat treatment.

8. the preheating area is equipped with 2 fire sickles, the bottom is designed with 2 partition walls, and the furnace is provided with a lift door to effectively prevent the loss of the protective atmosphere in the furnace, increase the pressure in the furnace, and reduce the amount of methanol.

9. The quenching furnace is equipped with flame waste heat recovery device, which can heat the cleaning liquid and save energy consumption.

10. The bottom of the furnace is provided with a debris removal port, which is convenient to clean up the debris in the furnace, keep the furnace clean and improve the service life of the equipment.

11. heating radiation tube: The isolation transformer low voltage and high current power supply mode, low design surface power, extend the life of radiation tube.

12. the control cabinet adopts centralized control, with safety alarm, process record and overtemperature alarm functions. The system is also equipped with industrial computer control, and all communication with instruments, frequency converters, PLC, etc. All parameters are controlled and recorded by the computer and can be permanently saved and queried.

13. Electrical components: instruments, air switches, contactors, thermal relays, micro relays, PLC and inverter all adopt international famous brands (Siemens, Mitsubishi, Omron, Fuji, Continental, Honeywell, etc.).

14. the temperature control instrument has PID intelligent control function, fast process response, small overshoot, high steady-state accuracy, temperature control heating system adopts pressure regulator, pressure regulator module (Ximenkang).

15. The computer touch screen to achieve full function operation, equipment operation at a glance, (to achieve full computer control).

16. quenching furnace and tempering furnace each area has three ammeter, heating element problems can be found in time maintenance.

17. the furnace refractory insulation materials are all Isolite and Yixing Morgan thermal insulation cotton and brick.

18. the network belt operation is installed with automatic correction device, to eliminate the network belt deviation, effectively improve the service life of the network belt.

19. the furnace wall is made of 8mm leveling steel plate, the two ends and the top plate are made of 10mm leveling steel plate.

20. the top cover plate, radiation pipe, roller radiator, slag cleaning mouth are sealed with screws, effectively prevent the furnace body leakage, reduce the amount of protective atmosphere, to ensure the quality of products after treatment.

21. quenching tank: with heating, cooling and circulation functions, so that the quenching liquid temperature is constant, effectively ensure the consistency of product hardness after treatment.

22. cleaning machine: using immersion + spray + oil-water separation, effective removal of parts surface oil.

23. tempering furnace: Each area is equipped with a strong convection fan to ensure uniform temperature in the furnace and uniform hardness of products after tempering.

24. fan bearings and mixed bearings using air cooling and its own heat dissipation technology, to prevent water, blockage and water leakage caused by the hidden dangers.

25.the operation of the whole production line with safety interlock function, failure automatically stop the subsequent operation, and prompt the fault in real time.

Hot Sale

Characteristic:

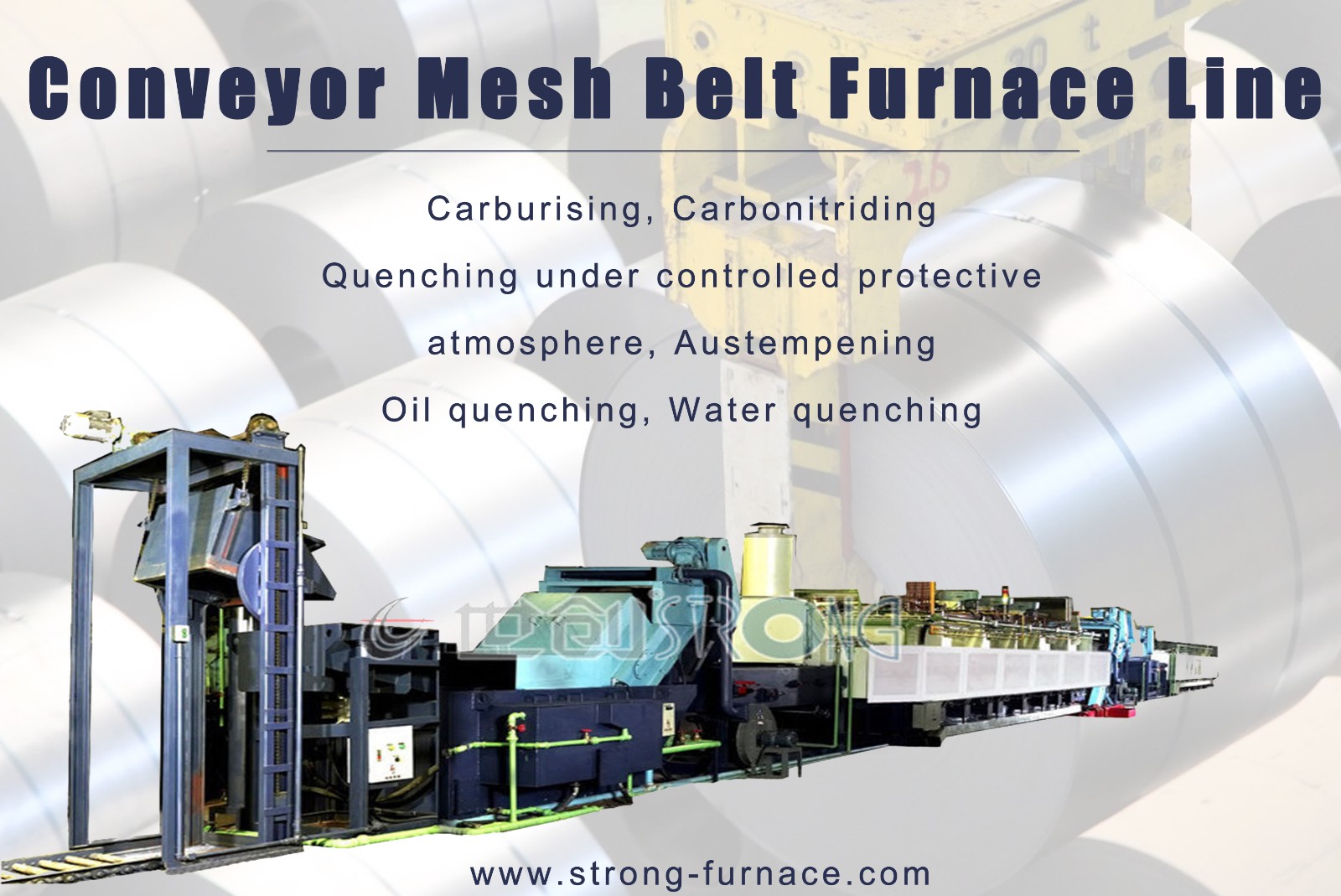

Intelligent heat treatment production line of mesh belt furnace is suitable for mass production of various small workpieces,such as carburizing, carbonitriding, quenching, oil quenching, water quenching and other heat treatment processes, processing screws, nuts, stamping parts, etc.

Design different heat treatment solutions according to your different workpieces.

Customized according to the product.

Performance: temperature 950 ℃; Material: shell: low carbon steel

Process: (1) carburizing, carbonitriding (2) controlled atmosphere quenching, isothermal quenching (3) oil quenching, water quenching

Advantage: computer control

Guangdong Strong Metal Technology Co., Ltd. is a trusted name among the mesh belt conveyor manufacturers in China. We are a globally accepted brand for all types of furnaces. We manufacture, supply and export well-designed and tailor-made furnaces as per the demands of our clients globally. We have created a name for ourselves as the best mesh belt furnace manufacturers in India.

We also have good market play as one of the best mesh belt furnace manufacturers in Vietnam for have contrstucted the latest conveyor there.