- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

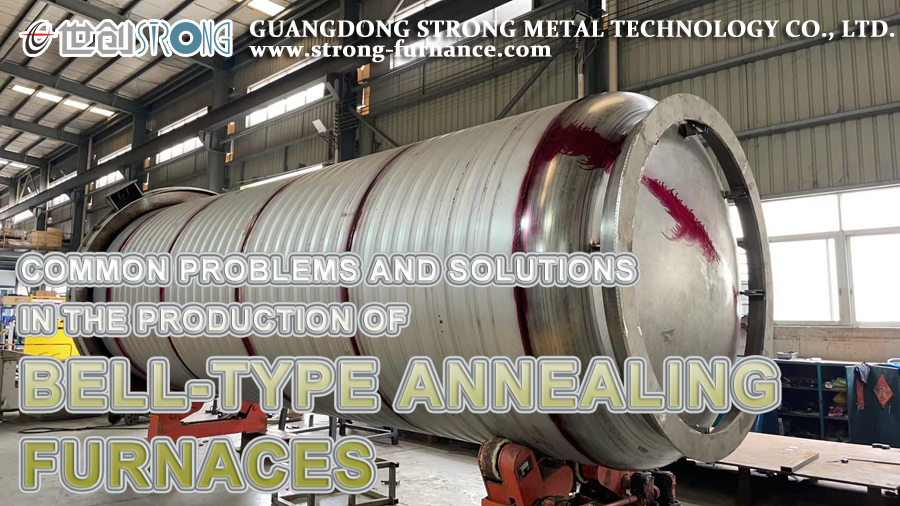

Common problems and solutions in the production of bell-type annealing furnaces

Common problems and solutions in the production of bell-type annealing furnaces

1. Hard rolling--the core hardness exceeds the allowable hardness of the product, resulting in quality non-conformity.

Cause: The insulation time is too short, and the mathematical model is biased.

Countermeasures: Test the temperature of the steel coil and calibrate the mathematical model.

2. Tensile strength is not consistent--the tensile strength and elongation fracture are inconsistent, and the grains are coarse.

Cause: The insulation time is too long, and the mathematical model is biased.

Countermeasures: Test the temperature of the steel coil and calibrate the mathematical model.

3. Carbon deposition on the surface--there is a carbon black layer on the surface of the steel coil out of the furnace.

Cause: Too much rolling oil, and the insulation time is too short at low temperature.

Countermeasures: Extend the low-temperature insulation time and check the speed of the circulating fan.

4. Yellowing of the surface--there are uneven yellow spots on the surface of the steel coil after it comes out of the furnace.

Cause: There may be water in the furnace, and the inner cover flange is not sealed.

Countermeasures: Monitor the dew point and replace the O-ring.

5. Sticking coils - there is adhesion between the strip layers. In severe cases, the two layers cannot be separated.

Reason: The insulation time is too long and the cooling process is wrong.

Countermeasure: Calibrate the mathematical model and optimize the cooling process

6. Curling - The edge of the steel coil bends inward after annealing, which is a major problem of the bell-type furnace.

Reason: The middle convection plate causes damage to the edge of the steel coil.

Countermeasure: The solution has been studied and there is a significant improvement.

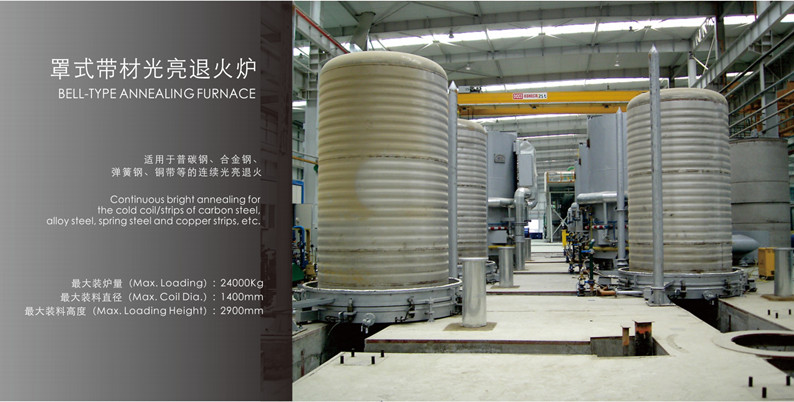

Strong Metal’s customized bell-type coil annealing furnace is suitable for bright annealing of carbon strip and alloy steel. The coil surface after annealing treatment is bright and the hardness is uniform. In addition, it can also be used for bright heat treatment of copper strip, wire, spring steel strip and wire.

After cold rolling the steel strip is hard and brittle. It has to pass a recrystallization annealing process to achieve the necessary ductility for the later cold forming process. Bell type furnace is also call batch annealing furnace.

Product Descrption:

1) bright annealing under protective atmosphere;

2) atmosphere gas can be ammonia decomposing gas or h2 hydrogen;

3) temperature automatically controlled by PLC system;

4) Processing production PLC control system;

5) module design, flexible and easy for production expansion in the future;

Specification:

Type: Bell type

Heating method: Gas, Electricity

Protective gas: Ammonia decomposing gas or hydrogen

Max. loading per bell: 24 tons

Max. coil dia: 1400mm

Max. loading height: 2900mm