- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

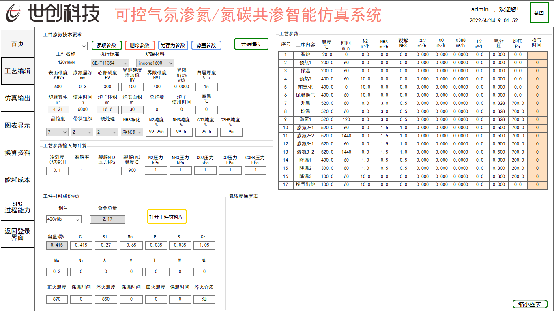

Controlled atmosphere nitriding and carbonitriding simulation system

With the development of the times. the alloy materials and composite materials required for new energy and clean energy emerge in an endless stream, and each component shoulders an important mission.

Stong Metal focuses on material heat treatment, participated in the formulation of a number of national heat treatment standards, has accumulated a large amount of process data, and developed a simulation system for controlled atmosphere nitriding and carbonitriding. These are all applied to intelligent flexible heat treatment center.

Controlled atmosphere nitriding and nitrocarburizing intelligent simlation system

Workpiece nitriding technical requirements-workpiece name, nitriding standard.surface hardness, nitriding layer depth, matrix hardness. Workpiece material-grain size level GB/T6394, band structure level GB/T13299, pretreatment level GB/T11354.

Workpiece material- collects a varity of nitriding material components, you can enter the material composition in the material menu, when the material grade is input, the average composition of the material is automatically input.

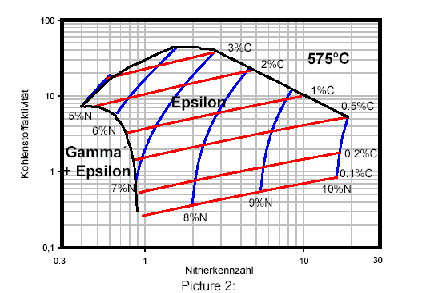

Process preparation menu-input nitriding temperature, time, process medium flow rate, when the input temperature, time and flow rate are not suitable, the intelligent expert system will automatically remind, and a reminder meny will pop up.

The intelligent system of this software will prompt that the parameters are unreasonable when the ammonia gas, cracked ammonia gas, carbon dioxide, carbon monoxide, hydrocarbon gas and atmosphere nitrogen potential, carbon potential or hydrogen content do not match, and the technicians will correct the changes in time.