Problems and modification of heating cover lining castable of bell type annealing furnace after 2 years of use

The heating cover of the bell type annealing heating furnace is exposed to a long-term working environment of alternating high and low temperatures, as well as a rising or falling working state, resulting in harsh working conditions. Causing cracks and detachment of the original furnace lining casting material, resulting in significant heat dissipation loss of the heating hood, severe energy consumption, and high temperature of the outer wall and burner area shell.

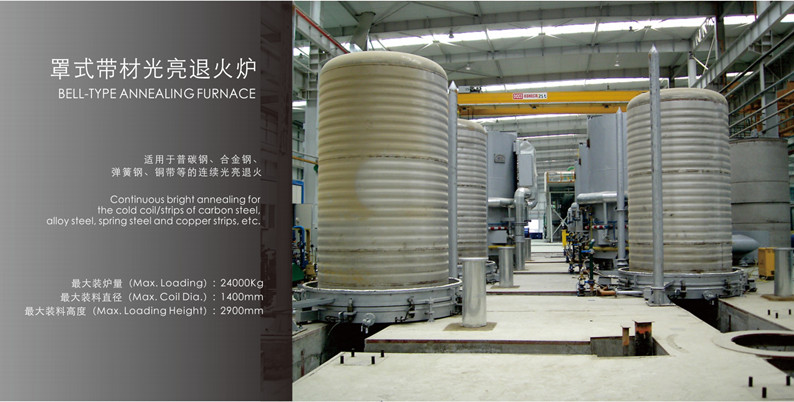

The working temperature of the heating cover used for annealing heating is around 850 ℃, which requires high requirements for refractory materials in the furnace lining. It is required that the furnace lining must have good fire resistance and thermal insulation effect, even if the hot surface temperature of the furnace lining reaches 850 ℃~900 ℃, and the average temperature of the outer wall of the heating hood remains ≤ room temperature+45 ℃, and the average temperature of the outer shell of the burner area remains ≤ room temperature+55 ℃. However, due to the cracking and detachment of the original lining casting material of the heating hood, the average temperature of the outer wall and the outer shell of the burner area is: the outer wall>75 ℃ (room temperature 20 ℃), and the outer shell of the burner area>85 ℃ (room temperature 20 ℃), which has exceeded the design temperature index. Therefore, renovating the refractory material of the heating hood lining of the annealing furnace can effectively reduce heat loss, lower the temperature of the outer wall and burner area shell, and reduce energy waste.

1: Existing problems

The heating cover is welded from a large structural steel and a sturdy electroplated cylinder. The refractory material for heating hood lining is mainly used as a castable structure, which has the following disadvantages:

(1) The furnace lining is made of cast material structure, and the outer wall temperature of the furnace top is too high, resulting in significant heat dissipation loss, severe energy consumption, and a harsh working environment.

(2) The lining material of the furnace is a heavy and lightweight castable structure. The thermal shock resistance and mechanical vibration performance of the lining material are poor, and cracks are prone to occur during use, leading to serious cracking and peeling of the castable lining, shortened service life, difficult maintenance, and high cost.

(3) The structure of the casting material for the furnace lining needs to be dried before use. If the drying effect is not good, it will affect the performance of the furnace lining.

2 Renovation plan

The selection of refractory materials is currently widely used in the application of bell type furnaces in China, and refractory ceramic fiber materials are used as refractory materials for furnace linings. Refractory ceramic fiber material is a lightweight and efficient insulation material. Compared with traditional insulation materials, it has the following advantages:

(1) Low volume density: Fiber furnace lining is more than 75% lighter than lightweight insulation brick furnace lining, and 90%~95% lighter than lightweight casting material furnace lining.

(2) Low thermal conductivity: At an average temperature of 400 ℃, the thermal conductivity of the refractory fiber furnace lining is<0.11 W/m.K, at an average temperature of 600 ℃ it is<0.16 W/m.K, and at an average temperature of 1000 ℃ it is<0.22 W/m.K, which is about 1/8 of that of lightweight clay bricks and 1/10 of that of lightweight heat-resistant lining (castable). The insulation effect is significant.

(3) High thermal sensitivity: The thermal sensitivity of refractory fiber furnace lining is much better than that of conventional refractory material furnace lining. Currently, heating furnaces are generally controlled by microcomputers, and the high thermal sensitivity of fiber furnace lining is more suitable for the automation control of industrial kilns.

(4) No need for oven drying: The furnace lining can be put into use after construction is completed, without the need for oven drying procedures.

(5) Easy construction: There is no need to leave expansion joints during the construction process, and the influence of construction technology factors on the insulation effect of the furnace lining is small.

(6) The disadvantages of refractory ceramic fiber furnace lining are that it is not wear-resistant, has poor thermal shock stability, and has poor resistance to thermal airflow erosion. This requires special attention. In long-term use, it can be found that ceramic fiber cotton will produce slag and clumping, and sometimes improper operation can cause clumping when lightly bumped. This may also be due to the fact that the material itself is a thermal insulation product.

Refractory fiber lining has become a trend in the current development of furnace lining, representing the level of modernization of industrial furnaces. The adoption of refractory fiber lining directly determines the effectiveness, product quality, and output of the furnace. Therefore, choosing refractory ceramic fiber material to replace the original furnace lining material meets the requirements for the use of the heating cover of the full hydrogen annealing furnace in the cold rolling plant.