- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

Process Flow Of Metalizing Furnace Production Line

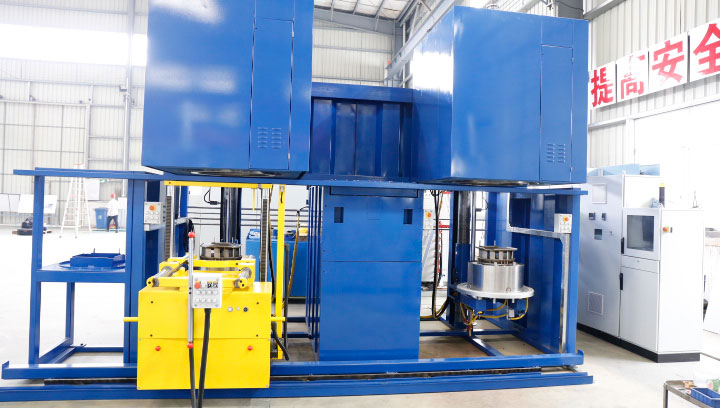

[Summary description] Metal infiltration furnace production line This production line is suitable for high and medium temperature heat treatment of workpieces under protective atmosphere (argon): depending on the different infiltration elements, different structures and properties can be obtained on the surface of the same material. It can make the surface of the material have excellent properties such as high temperature oxidation resistance, corrosion resistance and abrasion resistance. Equipment composition The metal infiltration production line is composed of 2 bottom-loading vertical multi-purpose furnaces, 1 argon cold tank, 1 supporting loading and unloading trolley, loading table, electrical control system, gas control system, computer control management system and circulating water The cooling device and other devices are composed. Process flow This production line adopts the process flow of charging, conveying, closing the furnace door, exhausting, heating, heat preservation, cooling, and unloading. The metal infiltration furnace can be heated according to the heating rate to realize the process of step heating, step cooling and cooling along with the furnace. Application field This equipment can be used for gas-phase aluminizing of high-temperature alloys, stainless steel, intermetallic compounds and other material parts, as well as for gas-phase aluminizing of parts such as blades. It can be widely used in aerospace, weapons, petroleum, mining, ships, automobiles, hardware and other industries.