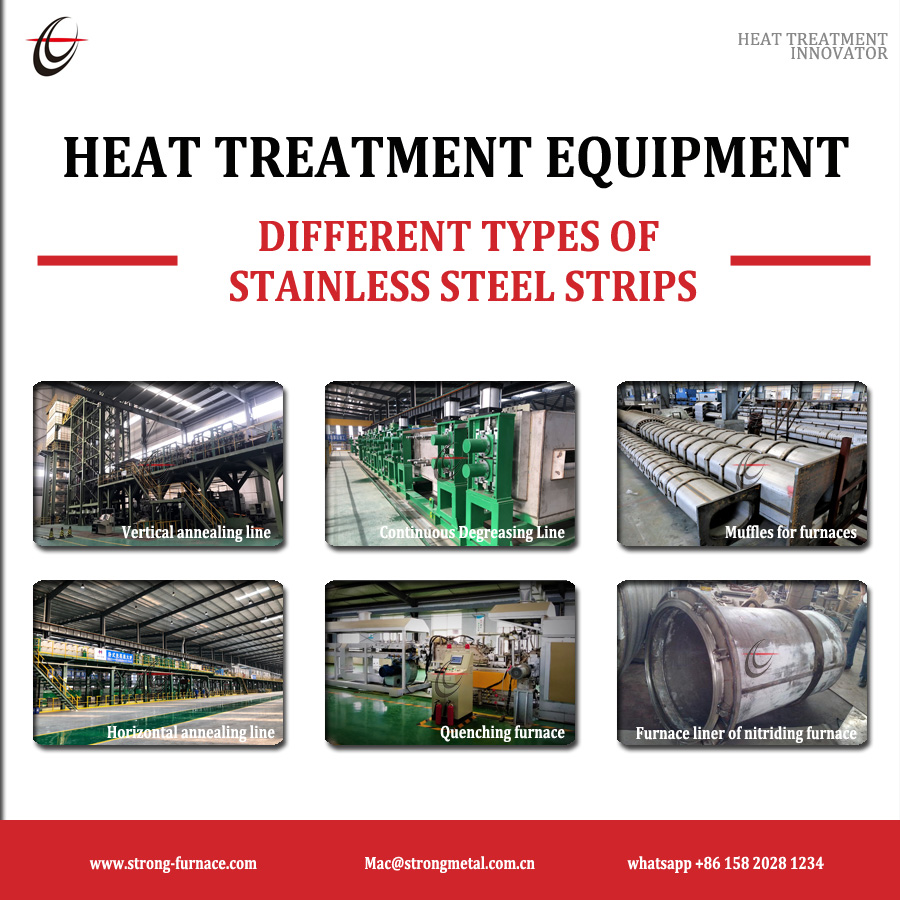

- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

Quickly get all kinds of steel coil quality problems!

Product quality is the foundation of the business, quickly GET all kinds of steel coil quality problems.

Professionals know that some steel coil quality problems will affect the user's winding, unwinding, lifting, if it is cold rolling, coating products will also affect the surface quality of the product, or even can not be used. There are many factors in the rolling process that lead to unqualified plates, of which the surface is the most prone to problems, sales personnel should learn to judge surface defects, to avoid quality problems products into the market, the following is some of the most common shape quality problems of hot rolled coil analysis.

1, tower shape:

part of the coil protruding or concave in the steel coil end plane. Cause: In the process of strip coiling, due to the wedge of the pinch roll, poor alignment when entering the coiling machine, sickle bending of the strip, large gap between the coiling rolls and other reasons, some of the coil layer of the inner ring of the steel coil protruding.

2, overflow edge:

part of the coil protruding or concave in the steel coil end plane. Cause: The cause is the same as the tower shape, but the bulge is relatively small.

3, coil layer dislocation:

part of the coil repeatedly protruding, concave in the steel coil end plane, uneven. Cause: the driving end of the drum is seriously worn, and there is a large centrifugal difference during rotation; The opening degree of the front side guide plate is too large, and the strip steel moves reciprocally in the axial direction.

4, inner ring loose coil:

steel coil inner ring coil layer loose, there is a large gap between the coil layer, serious visible lead collapse. Cause: the setting of winding tension is unreasonable; After winding, the reel is reversed.

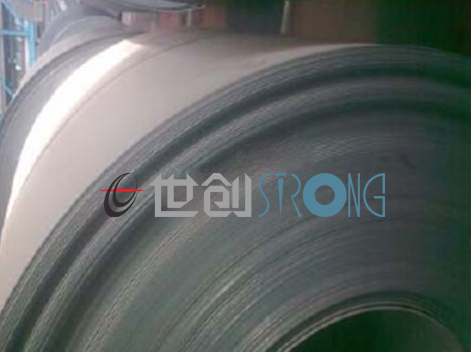

5, outer ring loose coil:

steel coil outer ring coil layer loose. Causes: the tape is broken, the outer ring part of the roll loose; Manual binding, the band is not tightened.

6, flat coil:

visually observe the steel coil as a whole oval. Cause: The whole steel coil collapses due to high coiling temperature, long time horizontal stacking, high horizontal stacking, loose coiling layer under small coiling tension, and large impact during lifting.

STRONG TECH has this professional commissioning team to escort your production line!Our designers effectively improve the quality of steel coils through professional design.

The key components of the horizontal continuous bright annealing line:

1) Uncoiler unit

2) Hydrolic shears

3) Welder

4) Rollers

5) Loopers

6) Degreasing unit

7) Annealing unit

8) Recoiler unit

9) Furnace control system

10) Driving control system

The procedure of the horizontal continuous bright annealing line:

Coil loading--Shear cutting--Welding-Inlet looper-Degreasing-Heating-Cooling-Outlet looper-Coil unloading

And finally, welcome to contact and cooperate with our company to achieve win-win situation!