- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

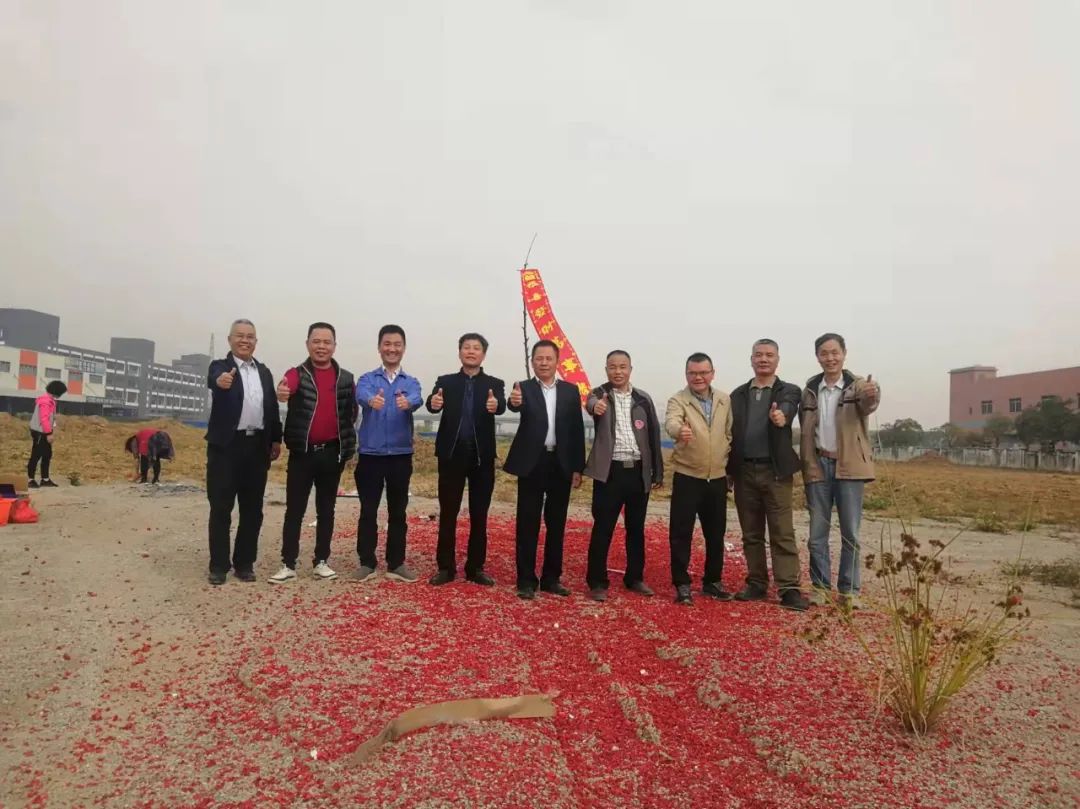

STRONG TECHNOLOGY - Jiangmen Factory (Jiangmen Strong Intelligent Technology Co., Ltd.)

Starting construction on June 28th, 2021

Foundation laid on December 11th, 2021

Jiangmen Strong Intelligent Technology Co., Ltd. under construction on June 30th, 2022

Successfully settled on March 12th, 2023

The construction of Jiangmen Strong Intelligent Technology Co., Ltd. has been a major focus of Strong Technology in recent years, producing high-end heat treatment intelligent equipment and a new type of intelligent production base for the industrialization of new materials. It mainly engages it he research and development of heat treatment intelligent equipment, metal material processing and heat treatment processing, industrial robots and automation technology, intelligent manufacturing system integration, and is applied in industries such as aerospace, weapons and ships, new energy vehicles, electronic devices, and metal products. When completed, the project will become the most powerful base for research, development, manufacturing and processing of new metal materials in South China.

It took a total of one and a half years from project initiation to entry, which is money, and efficiency is life. Give a thumbs up to our Shunde people.

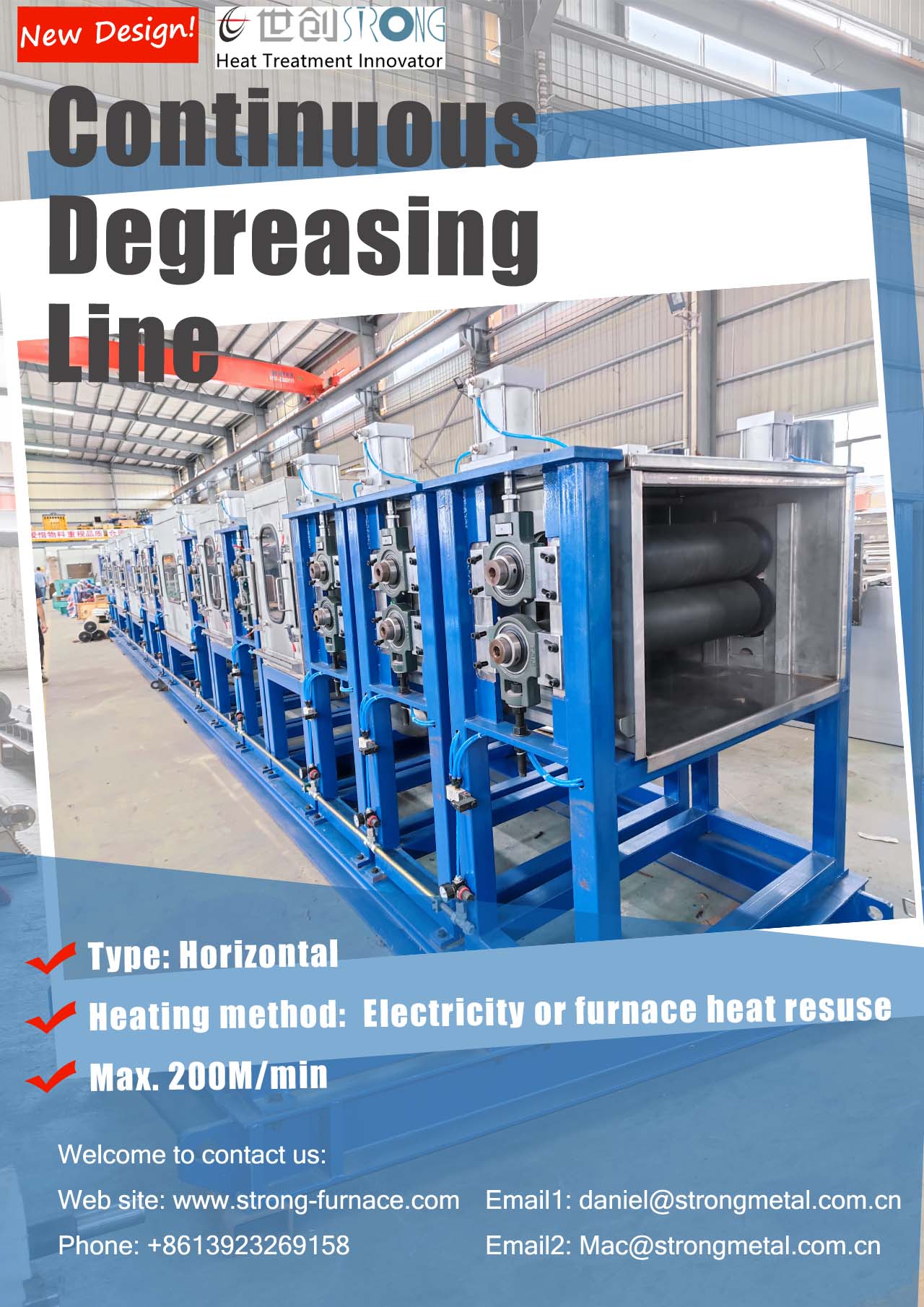

Degreasing lines are used to remove oil, grease, and other contaminants from metal parts. They are typically used in the metalworking industry, but they can also be used in other industries, such as the automotive and aerospace industries.

Degreasing lines typically consist of the following components:

A conveyor system: This system is used to transport the metal parts through the line.

A pre-wash station: This station is used to remove loose dirt and debris from the metal parts.

A degreasing tank: This tank is filled with a degreasing solution, such as an alkaline or solvent-based solution.

A rinse station: This station is used to rinse the metal parts with water.

A drying station: This station is used to dry the metal parts.

The degreasing process typically takes place in two stages:

The metal parts are immersed in the degreasing tank. The degreasing solution dissolves the oil, grease, and other contaminants on the metal parts.

The metal parts are rinsed with water to remove the degreasing solution.

The benefits of using degreasing lines include:

Improved cleanliness: Degreasing lines can remove oil, grease, and other contaminants from metal parts, which improves their cleanliness.

Reduced corrosion: Degreasing lines can help to reduce corrosion by removing oil and grease, which can attract moisture.

Improved surface finish: Degreasing lines can improve the surface finish of metal parts by removing contaminants that can cause the surface to be dull or rough.

The disadvantages of using degreasing lines include:

High initial investment: Degreasing lines are a significant investment.

Complex operation: Degreasing lines are complex to operate and maintain.

Specific requirements: Degreasing lines require specific materials and conditions to operate effectively.

Here are some of the different types of degreasing lines:

Alkaline degreasing lines: These lines use alkaline solutions to remove oil, grease, and other contaminants from metal parts.

Solvent degreasing lines: These lines use solvents to remove oil, grease, and other contaminants from metal parts.

Ultrasonic degreasing lines: These lines use ultrasonic waves to remove oil, grease, and other contaminants from metal parts.

The type of degreasing line that is used will depend on the specific requirements of the application. For example, alkaline degreasing lines are typically used for removing oil and grease from metal parts that will be painted, while solvent degreasing lines are typically used for removing oil and grease from metal parts that will be used in electrical applications.