- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

The key delivery finishes of stainless steel coil or strip or sheet

2E

Surface overview: Hot rolled black skin coils are used to directly roll the black skin through a continuous rolling production line, and then undergo solution annealing, phosphorus breaking and electrolytic pickling to form the surface. The surface has low roughness and good surface quality, providing stable and reliable blanks for subsequent orders for "special materials" and cold-rolled thin materials.

Process route: hot-rolled black skin coil—black skin straight rolling—annealing—phosphorus breaking—pickling—coil/plate finished product

Covered steel grades: 200 series, 300 series, 400 seriesThickness range: 1.0mm-3.0mm

2D

Surface overview: After the material is cold-rolled and rolled, the strip is continuously annealed to change the structure and the mechanical properties of the material to meet the mechanical properties required by the customer; then electrolysis and pickling are used to remove the oxidized scale on the surface of the steel strip, and then subjected to drawing Correct the plate shape.

Process route: raw material NO.1/2E—rolling—degreasing cleaning—annealing—electrolysis—pickling—stretching and straightening—finished coil/plate

Covered steel grades: 200 series, 300 series, 400 series

Thickness range: 0.25mm-3.0mm

2B

Surface overview: After the material is cold-rolled and rolled, the strip is continuously annealed to change the structure grain and the mechanical properties of the material to meet the mechanical properties required by the customer; then electrolysis and pickling are used to remove the oxide scale on the surface of the steel strip, and then adjusted Quality rolling and stretching corrects the plate shape and enhances the surface fineness.

Process route: raw material NO.1/2E—rolling—degreasing cleaning—annealing—electrolysis—pickling—tempering and rolling—stretching and straightening—finished coil/plate

Covered steel grades: 200 series, 300 series, 400 series

Thickness range: 0.25mm-3.0mm

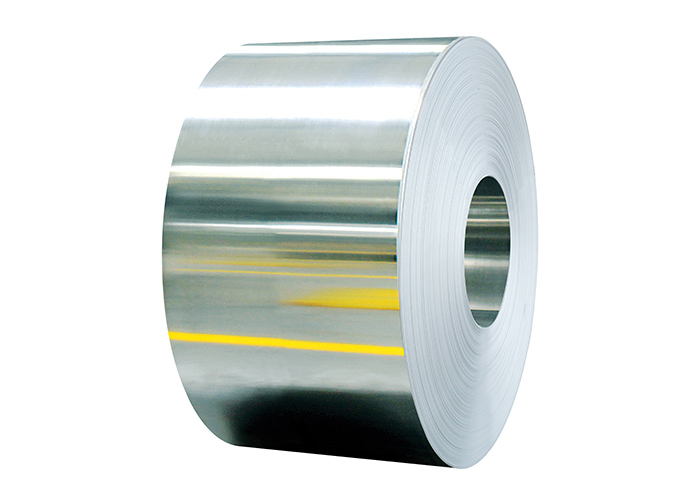

BA

Surface overview: After 2E material is rolled by high-precision 20-roll cold rolling, degreasing and bright annealing production lines are used to make the strip annealed in an oxygen-free environment to change the structure, grain and mechanical properties of the material to meet the mechanical properties required by the customer; Quenched and tempered rolling to correct the shape and improve the surface fineness.

Process route: raw material 2E—20 roll rolling—vertical/horizontal bright annealing—tempered and tempered rolling—coil/plate finished product

Covered steel grades: 200 series, 300 series, 400 series

Thickness range: 0.25mm-1.5mm

----end----

Guangdong Strong Metal Technology Co.,Ltd. is a professional supplier of industrial furnaces with over 30 years' experience. we have supplied over 200 annealing lines for most key stainless steel mills in the globe.

bright annealing line(BAL) for BA stainless steel coils

Annealing and pickling line(APL) for 2E/2E/2B