- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

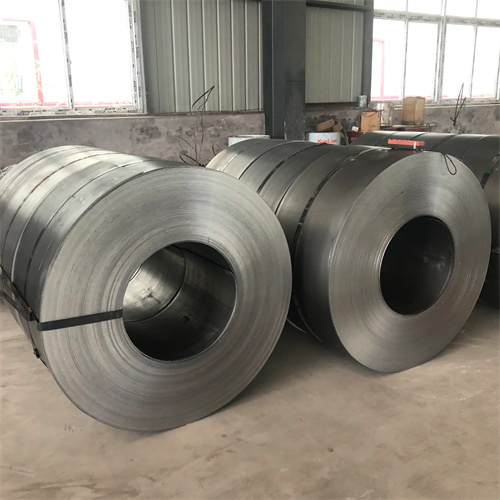

What is the difference between cold rolled plate and hot rolled plate

Plate is one of the essential building materials in modern architecture, and there are many types of plate, including cold-rolled plate and hot-rolled plate, what are the differences between cold-rolled plate and hot-rolled plate?

First, the difference between cold rolled plate and hot rolled plate

Different colors

The two rolled plates are different, the cold-rolled plate is silver, and the hot-rolled plate has more color, and some are brown.

2, feel different

Cold rolled sheet feels fine and smooth, and the edges and corners are neat. The hot-rolled plate feels rough, and the corner treatment is not very neat.

3. Different characteristics

The strength and hardness of cold-rolled sheet are high, and the production process is more complex, and the price is relatively high. The hot-rolled plate has lower hardness, better ductility, more convenient production and lower price.

Second, how to buy cold rolled plate

Packaging

Divided length and cold-rolled coil two kinds of packaging. The common packaging is iron sheet, lined with moisture-proof paper, and tied with iron waist, which is more secure to avoid friction between the cold rolled coils inside.

2. Specifications and dimensions

The relevant product standards specify the recommended standard lengths and widths of cold-rolled coils and their allowable deviations. The length and width of the volume must be determined according to user requirements.

3, appearance surface state:

The surface state of cold rolled coil is different due to different treatment methods in coating process.

4, galvanized quantity galvanized quantity standard value

Galvanizing quantity indicates the effective method of zinc layer thickness of cold rolled coil, and the unit of galvanizing quantity is g/m2.

5. Mechanical properties

Tensile test: Only structural and tensile properties are required. Bending test: It is the main item to measure the process performance of sheet metal. After the cold-rolled coil is bent for 180o, no zinc layer is separated from the outer surface, and no cracks or fractures occur on the plate base.

Summary: The above is about the difference between cold rolled plate and hot rolled plate and what is the whole content of cold rolled plate, I hope to help you.

Today's introduction——

continuous annealing furnace

A continuous annealing furnace (CAF) is a type of industrial furnace that is used to heat and cool metal wire, strip, or sheet in a continuous manner. CAFs are typically used to anneal steel, but they can also be used to anneal other metals such as copper, aluminum, and nickel.

The basic principle of a CAF is to pass the metal through a series of heating and cooling zones. The temperature and time spent in each zone is carefully controlled to achieve the desired annealing effect. The annealing process softens the metal and improves its ductility, which makes it easier to work with.

CAFs are typically large and complex pieces of equipment. They can be either batch or continuous furnaces. Batch furnaces heat and cool the metal in a series of chambers, while continuous furnaces heat and cool the metal as it passes through a long chamber.

CAFs are used in a wide variety of industries, including the automotive, aerospace, and electronics industries. They are an essential part of the manufacturing process for many metal products.

Here are some of the benefits of using a continuous annealing furnace:

Increased productivity: CAFs can process large quantities of metal in a short amount of time, which can lead to increased productivity.

Improved product quality: The annealing process can improve the quality of the metal, making it stronger and more ductile.

Reduced costs: CAFs can help to reduce costs by reducing the amount of energy used and the amount of waste produced.

If you are looking for a way to improve the quality and productivity of your metal manufacturing process, a continuous annealing furnace may be a good option for you.