- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

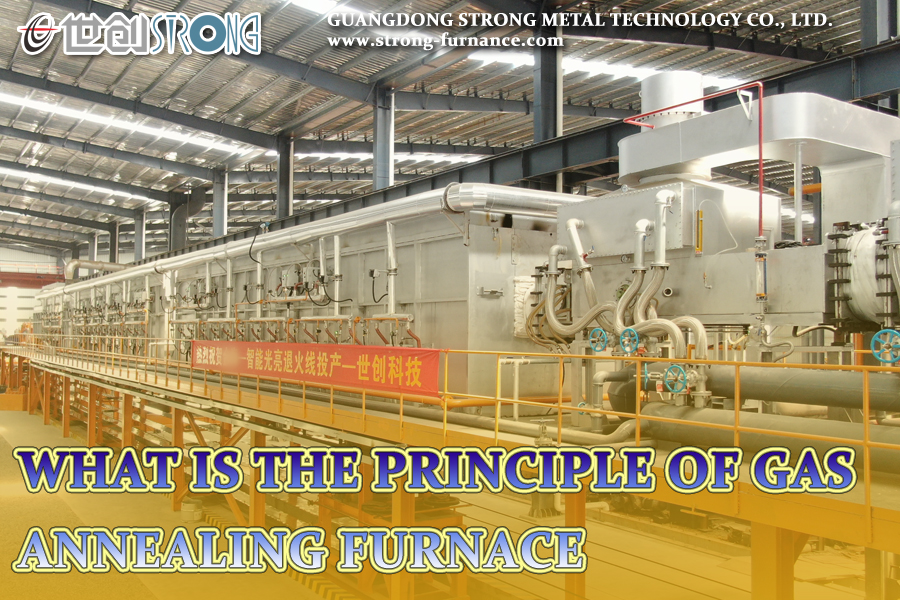

What is the principle of gas annealing furnace

1. Basic Principle of Gas Annealing Furnace

1. Basic Principle of Gas Annealing Furnace

Gas annealing furnace is a kind of equipment used for annealing metal. Its basic principle is to use the high-temperature gas generated by the combustion of gas to gradually grow the metal grains and achieve the desired softening effect through heating.

2. Working Principle of Gas Annealing Furnace

Gas annealing furnace is mainly composed of combustion system, heating system and control system. When the gas enters the combustion system, the gas is ignited by the igniter to generate a flame. The high-temperature gas generated by the flame is introduced into the heating system by the induced draft fan in the furnace. The heating system consists of multiple heating furnaces, and the metal workpiece is placed in the heating furnace. The high-temperature gas passes through the heating furnace to heat the metal workpiece.

3. Control Principle of Gas Annealing Furnace

The control system of the gas annealing furnace realizes automatic control of the heating and cooling of the furnace by measuring the temperature, pressure and other parameters in the furnace. The control system is usually composed of temperature sensors, pressure sensors, control valves and other components. When the temperature of the metal workpiece reaches the set annealing temperature, the control system will automatically shut down the heating system and enter the cooling stage.

4. Advantages of gas annealing furnace

Compared with other annealing methods, gas annealing furnace has the following advantages:

1. Good temperature uniformity: The heating system in the gas annealing furnace can provide high-temperature gas evenly and stably, so that the temperature of the metal workpiece is evenly distributed.

2. Easy operation: The control system of the gas annealing furnace can realize automatic control. The operator only needs to set the required temperature and time, and the rest of the work is automatically completed by the furnace.

3. Environmental protection and energy saving: The gas annealing furnace uses gas as fuel, and the combustion produces less waste gas, which reduces the pollution to the environment. At the same time, gas, as a clean energy, has the advantage of energy saving.

5. Application fields of gas annealing furnace

Gas annealing furnace is widely used in the metal processing industry, especially in the following fields:

1. Automobile manufacturing industry: used for annealing automobile parts to improve the wear resistance and toughness of parts.

2. Machinery manufacturing industry: used for annealing mechanical parts to make them have better processing performance.

3. Electronics industry: used for annealing electronic devices to improve their electrical properties.

Summary

The gas annealing furnace is a device that uses high-temperature gas generated by gas combustion to anneal metal. Its working principle is to gradually grow the metal grains through heating and achieve the desired softening effect. The gas annealing furnace has the advantages of good temperature uniformity, simple operation, environmental protection and energy saving, and is widely used in automobile manufacturing, machinery manufacturing and electronics industries.

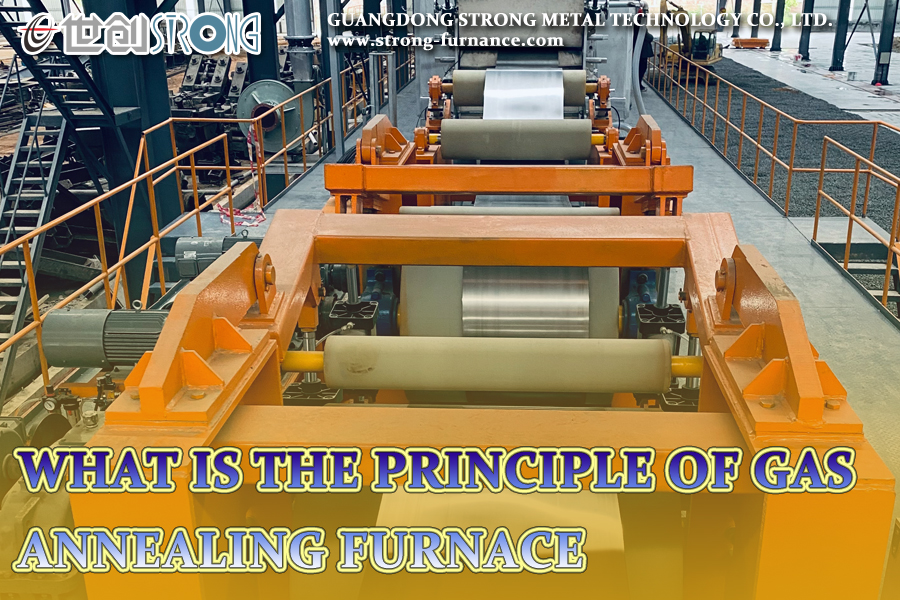

Strong Metal’s customized continuous stainless steel strip bright annealing line

Usage: Used for continuous bright annealing of stainless steel strips, plain steel, alloy steel, spring steel, copper, etc.

Thickness: 0.1~3MM

Width: 250~1450MM

Natural gas (LNG), liquefied petroleum gas (LPG), and diesel can be selected as the main heating methods of the furnace.

The unit of the stainless steel strip bright annealing line consists of an inlet section, an inlet looper, a degreasing section, a process section, an outlet looper, and an outlet section.

It adopts automated control to form an ultra-highly integrated and precision-controlled production line, realizing technological integration and innovation of stainless steel cold-rolled strip continuous lines.

Features: fast heating speed, low energy consumption, low cost, safe and reliable, high degree of automation and customizable.

Scope of application: widely used in metallurgy, special steel, and precision strip industries.