- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

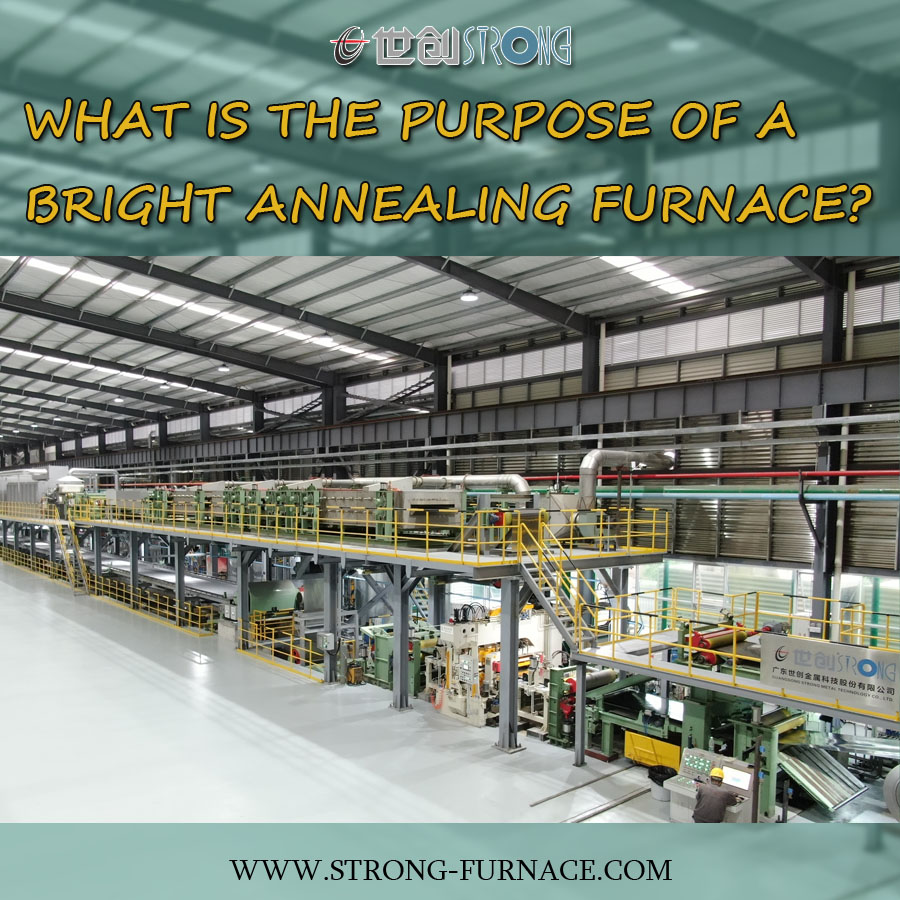

What is the purpose of a bright annealing furnace?

1. Eliminate work hardening and obtain satisfactory metallographic structure. When the performance requirements are different, the requirements for metallographic structure after bright annealing are also different, and the process of bright heat treatment is also different.

2. The surface is bright, corrosion-resistant, and free of oxidation. Bright annealing is the heat treatment of strip steel in a mixed gas atmosphere of hydrogen and nitrogen. By strictly controlling the protective atmosphere in the furnace, especially purity and residual oxygen, a bright surface without oxidation is obtained. Compared with the surface obtained by ordinary annealing and pickling, due to the absence of oxidation process, the chromium deficiency on the surface of the strip steel is reduced, and its corrosion resistance is better than that of the polished 2B plate.

3. Bright treatment maintains the smoothness of the rolled surface, and a bright surface can be obtained without the need for post-treatment. After bright annealing, the surface of the steel strip retains its original metallic luster and obtains a shiny surface close to a mirror. Under general requirements, its surface can be directly used without the need for processing.

4. Strip steel with special rolling pattern surface can be developed. Due to the fact that the surface of the steel strip is not changed during the annealing process, the rolled surface pattern can be completely retained, making it convenient to develop cold-rolled special patterned steel strips.

5. There is no pollution problem caused by ordinary pickling methods, and the annealed strip steel does not require pickling or similar treatment. Various media such as acid are not used, and there is no pollution problem caused by pickling,

6. To achieve control over the shape of the strip, as the design inside the bright annealing furnace allows for segmented adjustment along the width direction of the strip, the cooling speed in the width direction of the strip can be adjusted through air flow guidance, achieving online control of the shape of the strip,

Improvement measures:

The temperature of the renovated bright annealing furnace is divided into three zones. At the same time, by pushing the machine into the furnace zone - heating zone, four staggered burners are placed on both sides of the furnace wall. Bricks are built into tracks, and bricks or stones are built into arched supports to heat the components on both sides. To the front are two and three zones - constant temperature zone, two side wall heights, and four burners are staggered.

All eight burners are low-pressure vortex burners, and there are two composite metal heat exchangers on the top of the furnace in front and behind. The bottom of the furnace on both sides of the wall is a brick structure, and the top of the furnace is made of refractory fiber felt. High pressure fans are used to supply combustion air and exhaust air.

In the gas main pipe, the air main pipe is equipped with a regulating valve and a flow orifice plate. In the injected air main pipe, there is also a regulating valve, as well as a set of microcomputer control system, instruments and protection equipment.