Why does 304 precision stainless steel strip surface appear "ash" defect phenomenon?

Why does 304 precision stainless steel strip surface appear "ash" defect phenomenon? Which process is the problem? Is there a remedy or what can be done to avoid this "ash" defect?

As we all know, precision stainless steel belt as a high-end product of stainless steel, because of its excellent strength, accuracy and surface finish, it is widely used in aerospace, military defense, automobile manufacturing, electronic instruments, home appliances, computers and other high-tech fields.

The production process of precision stainless steel belt has high requirements for production equipment and production technology. The production line is a system production line consisting of rolling mill, bright annealing furnace, leveling equipment, drawing and straightening equipment, slitting equipment, cutting equipment and other equipment. Any problem in any link will affect the quality of the finished product of the precision stainless steel strip.

The conventional cold-rolled annealed stainless steel coil (2B surface) is used as a raw material for manufacturing precision stainless steel strips, which usually requires better surface quality to avoid surface line scale defects.

The purpose of bright annealing of precision stainless steel strip, on the one hand, is to eliminate work hardening and obtain satisfactory organization; On the other hand, it is to obtain a bright surface without oxidation. The "ash" defect on the surface of 304 precision stainless steel strip is generated in the process of bright annealing, that is, in the annealing furnace. The microstructure of "ash" defect is white micro-particles. This defect phenomenon can not be removed even if it is re-cleaned, so there is no suitable remedy, and it can only be used on products that do not pay much attention to the appearance of the surface.

The reason for the defect is that 304 stainless steel matrix contains boron element, and the mass fraction is too high, and the protective gas N2 and H2 are prepared by ammonia decomposition in bright annealing treatment of the steel strip. N2 molecule is chemically stable and belongs to inert gas. Due to the residual ammonia in the ammonia decomposition atmosphere, it is pyrolysis at high temperature to produce [N], which is easy to combine with boron atoms to produce grayish-white powdery BN compound. In one sentence, it is concluded that the boron atoms in the material are easy to combine with the nitrogen atoms with higher activity of decomposition in the protective atmosphere, generate boron nitride and precipitate on the surface.

The 304 stainless steel coil used for processing precision steel strip stops adding boronferroalloy in the steelmaking process, and the mass fraction of boron element in the stainless steel matrix is controlled to be no more than 0.0015%, which is conducive to avoiding the occurrence of the "ash" defect of 304 precision stainless steel strip.

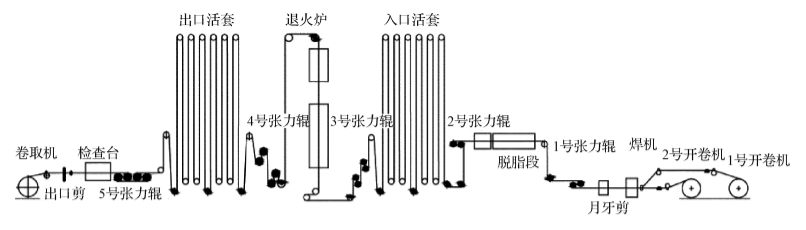

Daily introduction——Bright Annealing Lines:

A bright annealing line is a series of machines and furnaces that are used to heat and cool cold-rolled stainless steel strip in a controlled atmosphere. The goal of bright annealing is to produce a smooth, bright surface on the strip without any oxidation.

A typical bright annealing line consists of the following machines:

A degreasing unit to remove any oil or grease from the strip.

A preheating furnace to bring the strip up to a temperature of about 1000 degrees Fahrenheit.

A bright annealing furnace that is operated in an inert atmosphere, such as hydrogen or nitrogen. This prevents the formation of oxide on the surface of the strip.

A cooling furnace to bring the strip down to room temperature.

The strip is continuously fed through the bright annealing line at a speed of up to 100 meters per minute. The entire process takes about 30 minutes to complete.

Bright annealing lines are used to produce a variety of stainless steel products, including:

Kitchen utensils

Medical devices

Building materials

Automotive parts

Bright annealing lines offer a number of advantages over other methods of annealing stainless steel, including:

The strip is produced with a smooth, bright surface that does not require additional finishing.

The process is relatively energy-efficient.

The strip can be annealed in a continuous process, which reduces the time and cost of production.

However, bright annealing lines can also be expensive to purchase and operate. They also require a high level of technical expertise to operate properly.

Here are some of the benefits of using bright annealing lines:

Smooth, bright surface: Bright annealing produces a smooth, bright surface on the stainless steel strip without any oxidation. This makes the strip more aesthetically pleasing and easier to clean.

Energy efficiency: Bright annealing is a relatively energy-efficient process. The strip is heated in an inert atmosphere, which reduces the amount of energy required to heat the strip.

Continuous process: Bright annealing can be performed in a continuous process. This reduces the time and cost of production.

High production rates: Bright annealing lines can achieve high production rates. This makes them a good choice for large-scale production.

Here are some of the drawbacks of using bright annealing lines:

High cost: Bright annealing lines can be expensive to purchase and operate.

Technical expertise: Bright annealing requires a high level of technical expertise to operate properly.

Environmental impact: Bright annealing can have a negative environmental impact, due to the use of hazardous chemicals.

Overall, bright annealing lines are a valuable tool for the production of stainless steel strip. They offer a number of advantages over other methods of annealing, but they also have some drawbacks. The decision of whether or not to use a bright annealing line should be made on a case-by-case basis, taking into account the specific requirements of the application.