- Muffles for Furnaces

- Muffles For Horizontal Furnaces

- Muffles For Vertical Furnaces

- Muffles For Bell Furnaces

- Muffles For Carburizing Nitriding

- Muffles for conveyor furnaces

- Muffles For Ammonia Crackers

You must get the basic knowledge of stainless steel - the production process

Mori takes you to understand the process of stainless steel production!

First, stainless steel crude steel smelting process

At present, the smelting process of stainless steel production in the world is mainly divided into one-step, two-step and three-step methods, as well as new integrated production methods. One-step smelting process: hot metal +AOD (argon-oxygen refining furnace); The two-step process is: EAF (electric arc furnace) +AOD (argon-oxygen refining furnace). The three-step process is: EAF (electric arc furnace) +AOD (argon-oxygen refining furnace) + VOD (vacuum refining furnace).

In addition to several traditional production processes, the current integrated production process, that is, the production process from hot metal directly to stainless steel, is also used by many enterprises, the production process is: RKEF (rotary kiln furnace) +AOD (argon-oxygen refining furnace).

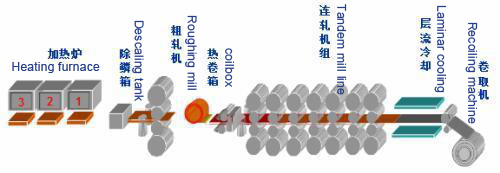

Second, stainless steel hot rolling process

Stainless steel hot rolling process is based on slab (mainly continuous casting billet) as raw material, which is heated to make strip steel from roughing mill and finishing mill. The hot steel strip from the last finishing mill is cooled to the set temperature by laminar flow, and is rolled into steel coils by the coiler. The cooled steel coils have oxide skin and appear black, commonly known as "stainless steel black rolls". After annealing and pickling, remove the oxidized surface, that is, "stainless steel white roll", most of the hot rolled products in the stainless steel market are stainless steel white roll. The specific stainless steel hot rolling production process is as follows:

Source: 51bxg

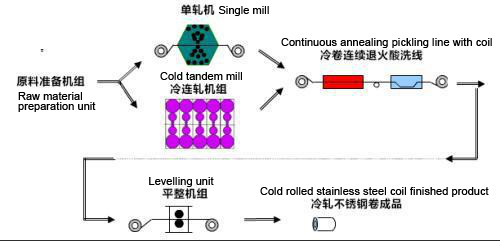

Third, stainless steel cold rolling process

After the hot rolling of stainless steel, some hot rolled stainless steel products are directly used downstream, and some hot rolled products need to continue to be processed into cold rolling and then used.

Stainless steel cold rolling, the use of hot rolled stainless steel products with a thickness of 3.0-5.5mm, after the rolling of cold rolling equipment, the production of stainless steel cold rolled products. At present, the main production process of stainless steel cold rolling is two types: stainless steel single stand cold rolling and stainless steel multi-stand cold rolling. The specific production process is as follows:

Source: 51bxg

After the stainless steel is cold-rolled, it needs to go through the annealing and pickling unit.

After cold rolling, the annealing of stainless steel is to eliminate the work hardening through the process of recrystallization and achieve the purpose of softening. The purpose of pickling is to remove the oxide layer formed on the surface of the steel strip during the annealing process, and to passivate the surface of the stainless steel to improve the corrosion resistance of the steel plate.