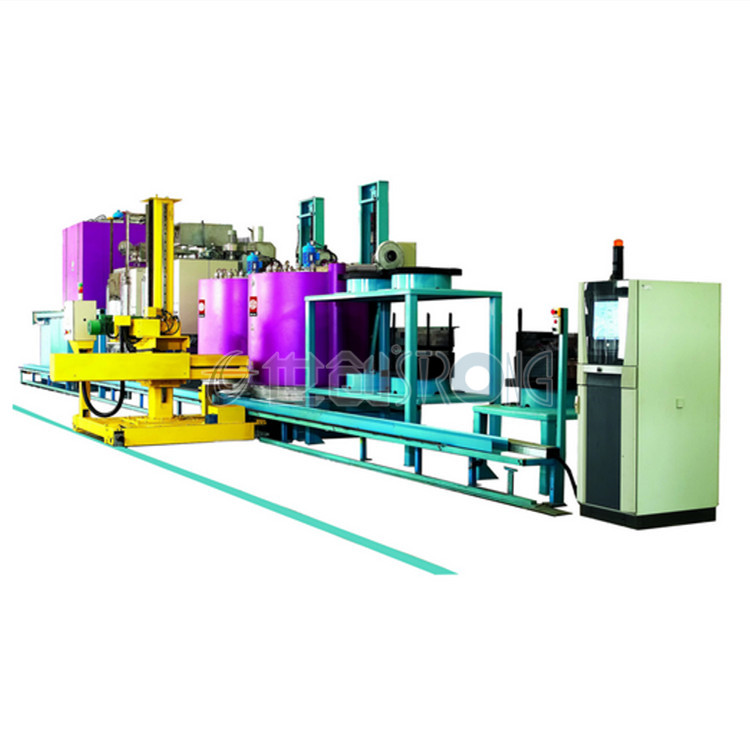

Heat treatment equipment for heat treating gears

Brand Strong

Product origin China

Delivery time 60

Supply capacity 100

This bell type furnace line adopting modular building block design, suitable for various processes and mass production requirements for under protective atmosphere annealing, tempering, queching, carburizing, carbonitriding, nitriding, ect. Heat treatment equipment for heat treating gears

Heat treatment equipment for heat treating gears

This bell type furnace line includes multiple bell type heat treatment furnace according particular production requirements. The heat treatment process includes charging, heating, transfer, quenching, unloading and other processes, which can realize controllable atmosphere protection quenching, annealing, tempering, carburizing, carbonitriding, nitriding, nitrocarburizing, oxygen nitriding Various heat treatment processes.

The bottom-loading vertical multi-purpose furnace adopts multiple patented technologies such as workpiece suspension, integrated fan, nitrogen blowing protection, and split quenching tank. The structure has high-quality metal furnace tank, advanced axial design, separation of furnace and quenching tank, and workpiece Four characteristics, such as direct quenching, form a unique new series of controllable atmosphere furnaces.

Heat treatment equipment for heat treating gears

Features:

1) Furnace gas atmosphere and temperature recover and change quickly, less gas consumption, convenient start-up and shutdown, fast process conversion, high production efficiency, energy saving, consumption reduction, and low operating cost.;

2) high-power circulating fans and good air guide devices are used for strong convection circulation, and the three-zone multiple thermocouples are associated with temperature control to ensure the uniformity of the furnace temperature and the uniformity of the atmosphere;

3) The cooling method can choose oil, hot oil (≤ 200℃), water, salt water, polymer, salt bath (130-550℃), air cooling (1~15bar) and other cooling media can be equipped with multiple combinations such as one furnace and one tank, one furnace and two tanks, and two furnaces and one tank, which are suitable for various heat treatment processes and various batch production. Particularly suitable for high-quality, small-batch, multi-variety production characteristics, and also the best solution to replace salt bath furnaces and lead bath furnaces to reduce pollution;

4) the maximum working temperature can reach 1050℃, which is suitable for high temperature carburizing and high temperature protective atmosphere heat treatment. The workpiece is directly and vertically quenched from the heating chamber, the quenching transfer time is short, and the heat treatment distortion is small;

5) Equipped with material and process database and automatic process expert system, with control from simple to complex process. It can be selected to realize real-time online control and production management, offline process simulation and data tracking, and remote control;

6)Adopting modular building block design, suitable for various processes and mass production requirements.

Video of heat treatment furnace

Specification:

| Model | Effective Heating Zone(mm) | Batch Loading(kg) |

| SP50 | 300x300x300 | 50 |

| SP80 | 300x300x600 | 80 |

| SP150 | 400x400x700 | 150 |

| SP300 | φ500x700 | 300 |

| SP500 | φ700x700/900/1100 | 500/600 |

| SP800 | φ900x900 | 800 |

| SP1000 | φ900x1100 | 1000 |

| SP1500 | φ1500x700 | 1500 |

| SP7000 | φ1500x4000 | 7000 |