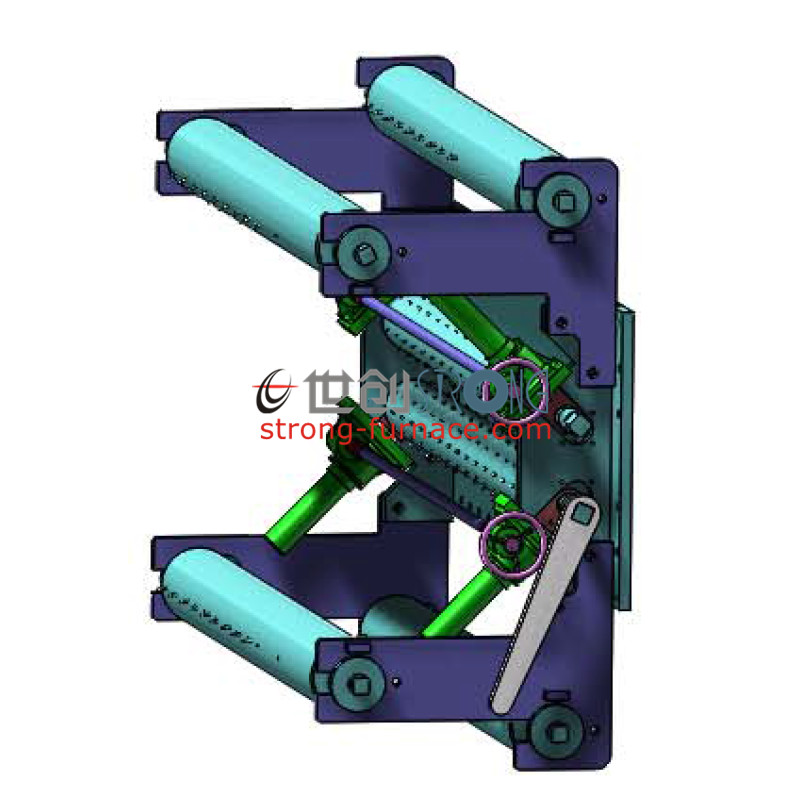

Woolen felt sealing device for bright annealing furnace

Brand STRONG

Product origin CHINA

Delivery time 180

Supply capacity 10

The sealing roller is a very important component for continuous bright annealing line for maintaining protective gas atmpshere for heat treatment of stainless steel strips. Strong Metal develops high effective sealing devices for this application in light with its experience in heat treating strips.

Download

Woolen felt sealing device for bright annealing furnace

In addition to steel industry, Srtong Metal also is active in copper & its alloy industry. Strong Metal provides heat treatment equipment for bright annealing cooper & alloy strips. Please feel free to contact Strong Metal for a particular heat treatment solution integrating into your production lines.

The Annealing process of this bright annealing line is operated under atmosphere protection free from oxidization. Specially designed and patented sealing device. Amonia decomposing gas or 100% Hydrogen optional. Please feel free to contact our sales engineer for more information.

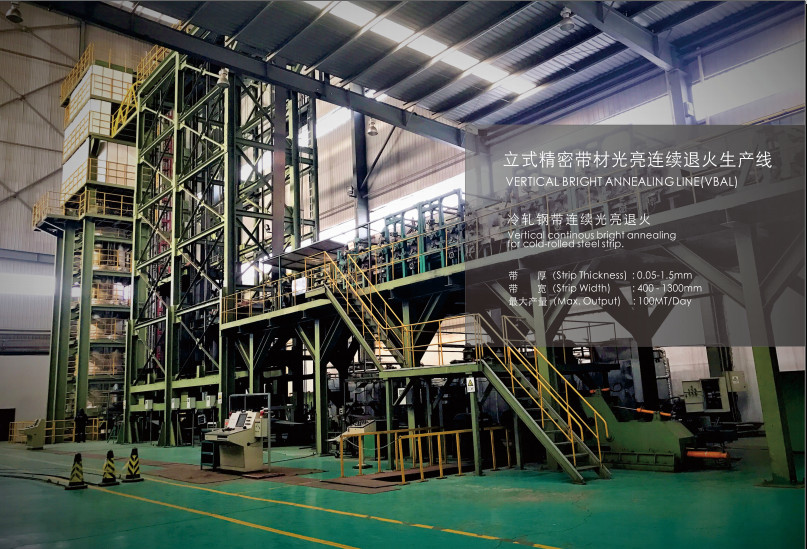

Vertical Continuous Bright Annealing Line(VBAL) for stainless steel industry

Vertical Bright Annealing Line

The furnaces and loopers are vertically arranged in this bright annealing line. This line has equiped with inlet and outlet loopers for purpose of continuous annealing process for heat treating steel strips or coils without interruption during loading or unloading materials.

The annealing process completely operates under controlled atmosphere with ammonia decomposing gas or hydrogen with strong patented concealing devices at the extrances of the furnaces.

This line is integrated with degreasing line for preprocessing the strips or coils before annealing process, which ensures high quality glossy quality of the surface.

This bright annealing line is equiped with strong metal's latest propriety technology on energy efficiency and environment protection.

Strong Metal is a leading supplier of continuous bright annealing lines for stainless steel cold roll mills. Strong Metal's exlcusive patented muffle with featured long time service. Excellent quality and best effeciency of Strong Metal heat treating equipment are the main factors why our customers choose us as their heat treatment equipment supplier in the long run.

Bright annealing is an annealing process performed in a vacuum or a controlled atmosphere containing inert gases (such as Ammonia decomposing gas, hydrogen). This controlled atmosphere reduces the surface oxidation to a minimum which results in a brighter surface and a much thinner oxide layer. Pickling is not needed after bright annealing since the oxidation is minimal. Since there is no pickling, the surface is much smoother which results in better resistance to pitting corrosion.

Application

Austenitic CrNi alloy steels

Ferritic Cr alloy steels

Martensitic Cr alloy steels

FeNi alloys

Si alloyed steels

Ti alloyed steels

Mn alloyed steels

Co alloyed steels

Clad steel strip

Duplex steels

Titanium and Ti alloyed steels

AlCr alloyed steels

Main Technical Parameters:

Annealing Materials:

Annealing Materials:

Grade: 200 300 400 stainless steel strips or coils

Thickness: 0.02-2.0mm

Width: 300-1350mm

Max. Output: 300mt/day

Equipment General Introduction:Applications: continuous bright annealing for the stainless steel strip in final products or middle products.

Layout Type: Horizontal

Heating Mode: Electricity or feul or gas

Protective Gas: Ammonia Decomposing Gas(75%H2+25%N2)or 100% H2

A brief introduction of Strong Metal

Guangdong Strong Metal Technology Co., Ltd.(StrongMetal) is public listed high tech company which is committed to develop and manufacture advanced heat treating equipment and provide customized heat treatment engineering for various industries including aerospace, steel, machinery, tool, automobile, electronics, home appliaces, contruction, ect.

StrongMetal Expertise covers comprehesive heat treatment processes such annealing, hardening, normalizing, tempering, carburizing, nitriding, carbonitriding, nitrocarburizing, ion plating ...

StrongMetal Equipment Manufacturing includes: Continuous vertical bright annealing line(BAL) for stainless steel strips;Continuous horinzontal bright annealing line(BAL) for stainless steel strips;Continuous pickling and annealing line(PAL) for steel strips;Mesh belt conveyor furnace for heat treating metal parts;Intelligent flexible heat treatment center;Horizontal hardening and tempering line;Bell-type furnace line;Bell-type nitridding furnace;Pit type carburizing furnace; Pit type vacuum impulse nitriding furnace;Bell-type vacuum cleaner..

Our advantages

Experience

Strong Metal has over 30 years’experience in heat treatment and has accumilated abundant know-how techniques which bring values to our customers.

Innovation

Strong Metal keeps continuous cooperation with high level universities and global companies for R&D on heat treatment technology which keep our customers’businesses forward-looking and competitive

Quality

Strong Metal ISO9001 quality management system employs strict control on equipment and materials provided by strong metal.

Team

Strong Metal is multi-disciplined team engaging in within 24 hours responsive global services for heat treatment equipment design, manufacturing, engineering, erection, commission, training.

Who we serve

Strong Metal provides various heating solutions for industries including steel industry, machinery, aerospace, automobile, arms, tool, home appliances, building, electronics, electrical.

Strong Metal enjoys great honor for serving customers some of which are the leaders in their industries, just name a few below: