PROTECTIVE ATMOSPHERE HEAT TREATMENT AND BRIGHT ANNEALING

PROTECTIVE ATMOSPHERE HEAT TREATMENT

Protective atmosphere heat treatment is to control the composition of the atmosphere during the heat treatment process to protect metal materials and prevent oxidation, corrosion and other reactions from occurring. This method can effectively improve the surface quality and mechanical properties of metal materials, and is widely used in steel, non-ferrous metals and other fields.

1. Types of protective atmosphere

Protective atmosphere is mainly divided into two categories: reducing atmosphere and inert atmosphere. Reducing atmosphere mainly includes hydrogen, hydrogen, carbon monoxide, etc. These gases have strong reducing ability at high temperatures and can effectively prevent the oxidation of metals. Inert atmospheres such as argon, nitrogen, etc. have stable chemical properties and will not react with metals, so they can provide effective protection.

2. Application of protective atmosphere heat treatment

Protective atmosphere heat treatment is widely used in the treatment of steel, copper, aluminum and other metal materials. For steel materials, the use of protective atmosphere heat treatment can significantly improve its surface finish and corrosion resistance, while improving its mechanical properties. For non-ferrous metals such as copper and aluminum, heat treatment in a protective atmosphere can effectively prevent oxidation and discoloration and maintain their original color and conductive properties.

3. Advantages of protective atmosphere heat treatment

The advantages of protective atmosphere heat treatment are mainly reflected in the following aspects: first, it can effectively prevent oxidation and corrosion of metals and improve surface quality; second, it can improve the mechanical properties of metal materials, such as increasing hardness, tensile strength, etc.; third, it can It maintains the original color and luster of metal materials and is suitable for occasions that require higher surface quality.

Bright annealing is a special heat treatment process that aims to change the internal crystal structure of metal materials by strictly controlling the heating and cooling process, thereby eliminating internal stress, improving plasticity and toughness, and maintaining the original color of metal materials.

1. Principle of bright annealing

The principle of bright annealing is to control the heating and cooling rates within a certain temperature and time range to orderly transform the crystal structure inside the metal material, thereby eliminating internal stress and improving plasticity and toughness. In this process, the surface quality of the metal material will also be significantly improved, showing a bright state.

2. Application of bright annealing

Bright annealing is mainly used for the treatment of steel, copper, aluminum and other metal materials. For steel materials, bright annealing can eliminate the internal stress generated during processing, improve its plasticity and toughness, and is suitable for the processing and manufacturing of precision parts. For non-ferrous metals such as copper and aluminum, bright annealing can maintain their original color and luster and improve their conductivity and corrosion resistance.

3. Advantages of bright annealing

The advantages of optical high annealing are mainly reflected in the following aspects: first, it can eliminate the internal stress inside the metal material and improve its plasticity and toughness; second, it can maintain the original color and luster of the metal material, which is suitable for applications with higher surface quality requirements. Third, during the bright annealing process, the surface of the metal material will not be oxidized or corroded, thus avoiding the degradation of surface quality caused by oxidation or corrosion.

IN CONCLUSION:

Protective atmosphere heat treatment and bright annealing are two important heat treatment processes for metal materials. Protective atmosphere heat treatment protects metal materials by controlling the composition of the atmosphere and prevents oxidation, corrosion and other reactions. It is widely used in steel, non-ferrous metals and other fields. Bright annealing changes the crystal structure inside the metal material by controlling the heating and cooling process to eliminate internal stress and improve plasticity and toughness. The application of these two processes can significantly improve the surface quality and mechanical properties of metal materials, which is of great significance for the processing and manufacturing of precision parts. In practical applications, it is crucial to select an appropriate heat treatment process based on factors such as the type of metal material, performance requirements, and usage conditions.

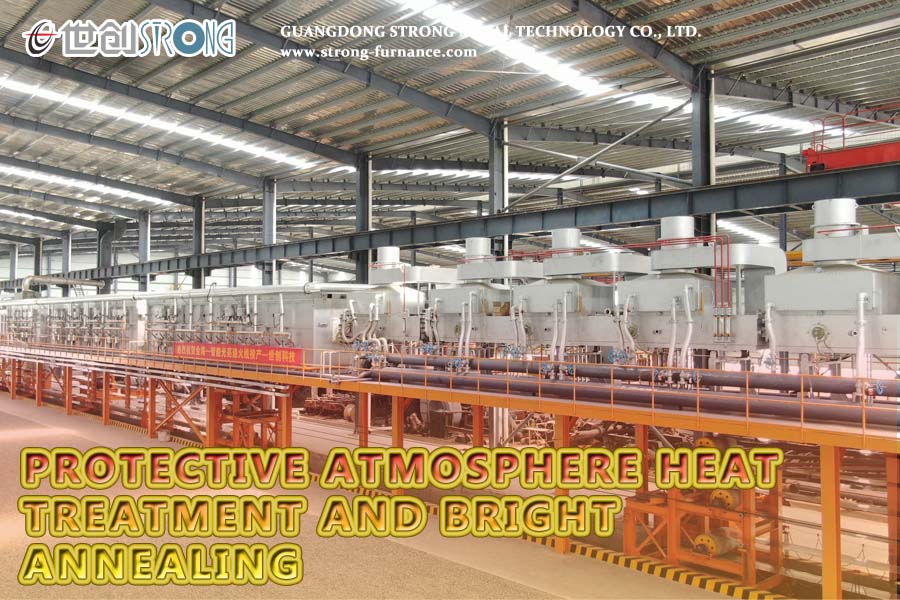

Strong Metal’s customized continuous stainless steel strip bright annealing line

Usage: Used for continuous bright annealing of stainless steel strips, plain steel, alloy steel, spring steel, copper, etc.

Thickness: 0.1~3MM

Width: 250~1450MM

Natural gas (LNG), liquefied petroleum gas (LPG), and diesel can be selected as the main heating methods of the furnace.

The unit of the stainless steel strip bright annealing production line consists of an inlet section, an inlet looper, a degreasing section, a process section, an outlet looper, and an outlet section.

It adopts automated control to form an ultra-highly integrated and precision-controlled production line, realizing technological integration and innovation of stainless steel cold-rolled strip continuous production lines.

Features: fast heating speed, low energy consumption, low cost, safe and reliable, high degree of automation and customizable.

Scope of application: widely used in metallurgy, special steel, and precision strip industries.

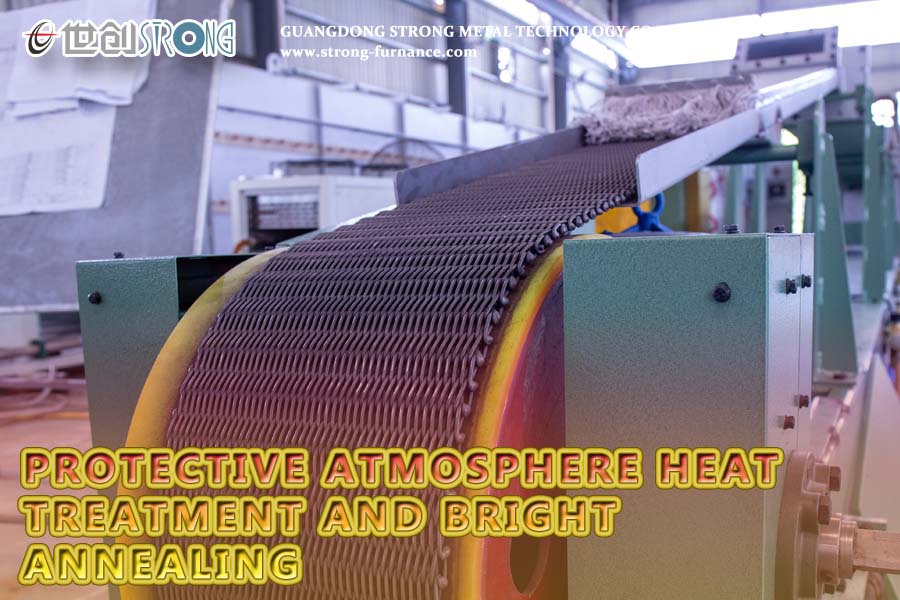

Conveyor Mesh Belt Furnace Line

Characteristic: Intelligent heat treatment production line of mesh belt furnace is suitable for mass production of various small workpieces,such as carburizing, carbonitriding, quenching, oil quenching, water quenching and other heat treatment processes, processing screws, nuts, stamping parts, etc.

Design different heat treatment solutions according to your different workpieces.

Customized according to the product.

Performance: temperature 950 ℃; Material: shell: low carbon steel

Process: (1) carburizing, carbonitriding (2) controlled atmosphere quenching, isothermal quenching (3) oil quenching, water quenching