What is rapid annealing?

Annealing is an important metal and alloy processing process in heat treatment production, which aims to improve the performance of materials by controlling heating and cooling. The essence of annealing is to heat the steel to austenitization and then perform pearlite transformation. The structure after annealing is close to the equilibrium structure.

Purpose of annealing:

1. Reduce hardness and strength and improve machinability.

2. Eliminate or reduce residual stress, stabilize size, reduce deformation and crack tendency.

3. Refine grains, adjust structure, and eliminate structural defects.

4. Uniform material structure and composition, improve material properties or prepare for subsequent heat treatment.

Classification of annealing methods:

1. Complete annealing

Heat the steel to 20~30℃ above Ac3, keep it warm for a period of time and then slowly cool it (with the furnace) to obtain a heat treatment process close to the equilibrium structure (complete austenitization).

Full annealing is mainly used for hypoeutectoid steel (wc=0.3~0.6%), generally medium carbon steel and low and medium carbon alloy steel castings, forgings and hot rolled profiles, and sometimes also for their welded parts. After full annealing, the hardness of low carbon steel is low, which is not conducive to cutting processing; when hypereutectoid steel is heated to an austenite state above Accm and slowly cooled and annealed, Fe3CⅡ will precipitate along the grain boundary in a network, which will significantly reduce the strength, hardness, plasticity and toughness of the steel, leaving hidden dangers for the final heat treatment.

2. Isothermal annealing

Heat the steel to a temperature higher than Ac3 (or Ac1), keep it warm for an appropriate time, cool it quickly to a certain temperature in the pearlite zone, and keep it isothermally to transform austenite into pearlite, and then air cool it to room temperature.

Full annealing takes a long time, especially for alloy steels with relatively stable supercooled austenitization. If the austenitized steel is quickly cooled to a temperature slightly lower than Ar1, A is converted to P, and then air-cooled to room temperature, the annealing time can be greatly shortened. This annealing method is called isothermal annealing.

3. Incomplete annealing

The steel is heated to Ac1~Ac3 (hypoeutectoid steel) or Ac1~Accm (hypereutectoid steel) and then slowly cooled after insulation to obtain a heat treatment process close to the equilibrium structure.

It is mainly used to obtain spherical pearlite structure in hypereutectoid steel to eliminate internal stress, reduce hardness, and improve cutting processability. Spheroidizing annealing is a kind of incomplete annealing.

4. Spheroidizing annealing

A heat treatment process that spheroidizes carbides in steel to obtain granular pearlite. Heating to a temperature of 20~30℃ above Ac1, the insulation time should not be too long, generally 2~4h is appropriate, and the cooling method usually adopts furnace cooling, or a longer isothermal time at about 20℃ below Ar1. Mainly used for eutectoid steel and hypereutectoid steel, such as carbon tool steel, alloy tool steel, bearing steel, etc.

5. Homogenization annealing

Heat the ingot, casting or forging to a temperature slightly below the solidus for a long time, and then slowly cool it to eliminate the chemical composition unevenness.

The heating temperature of diffusion annealing is very high, usually 100~200℃ above Ac3 or Accm. The specific temperature depends on the degree of segregation and the type of steel. The holding time is generally 10~15 hours. After diffusion annealing, complete annealing and normalizing treatment are required to refine the structure. It is mainly used for some high-quality alloy steels and alloy steel castings and ingots with severe segregation.

6. Stress relief annealing

Heat the steel to a temperature below Ac1 (usually 500~650℃), keep it warm, and then cool it with the furnace. The stress relief annealing temperature is lower than A1, so stress relief annealing does not cause structural changes.

7. Recrystallization annealing

Recrystallization annealing, also known as intermediate annealing, is a heat treatment process that heats the cold-deformed metal to above the recrystallization temperature and keeps it for an appropriate time to transform the deformed grains back into uniform equiaxed grains and eliminate work hardening and residual stress. For the recrystallization phenomenon to occur, there must first be a certain amount of cold plastic deformation, and secondly, it must be heated to above a certain temperature.

Annealing equipment:

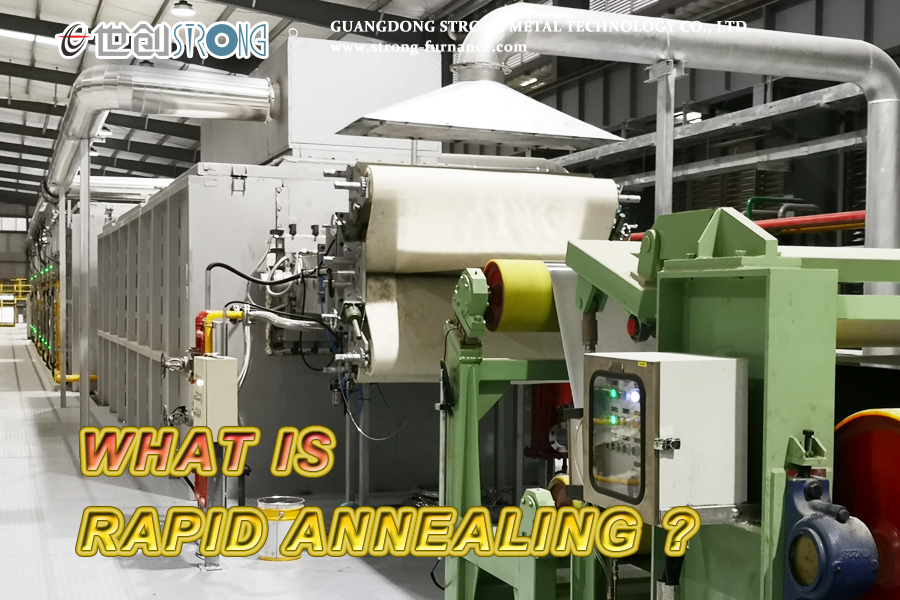

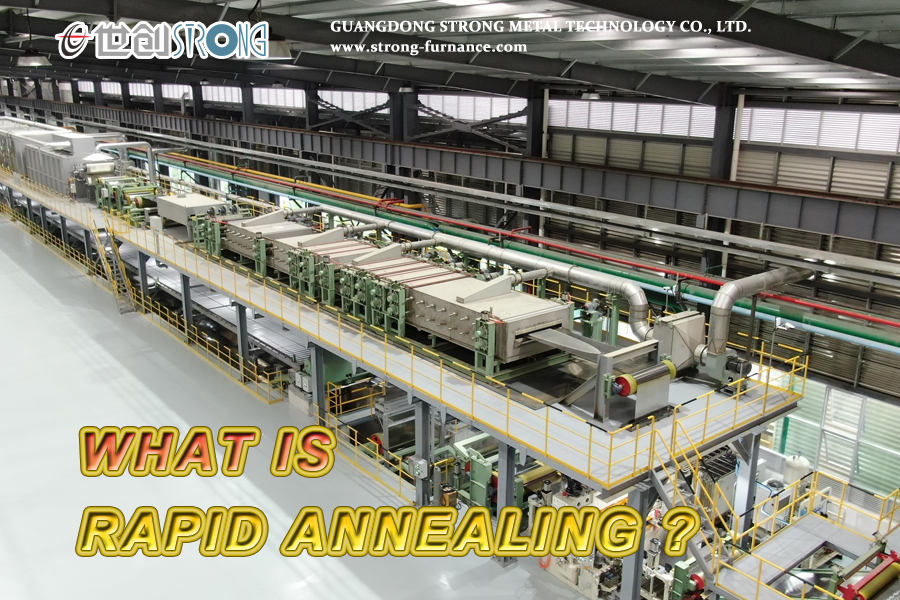

Strong Metal customized continuous stainless steel strip bright annealing line

Use: used for continuous bright annealing of stainless steel strip, ordinary steel, alloy steel, spring steel, copper, etc.

Strip thickness: 0.1~3MM

Band width: 250~1450MM

Natural gas (LNG), liquefied petroleum gas (LPG) and diesel can be selected as the main heating method for the furnace body.

The unit of the stainless steel strip bright annealing production line consists of an inlet section, an inlet looper, a degreasing section, a process section, an outlet looper, and an outlet section.

The use of automated control forms an ultra-highly integrated and precision-controlled line, realizing the technical integration and innovation of the continuous production line of stainless steel cold-rolled strip.

Features: fast heating speed, low energy consumption, low cost, safe and reliable, high degree of automation, and customizable.

Application range: widely used in metallurgy, special steel, and precision strip industries.