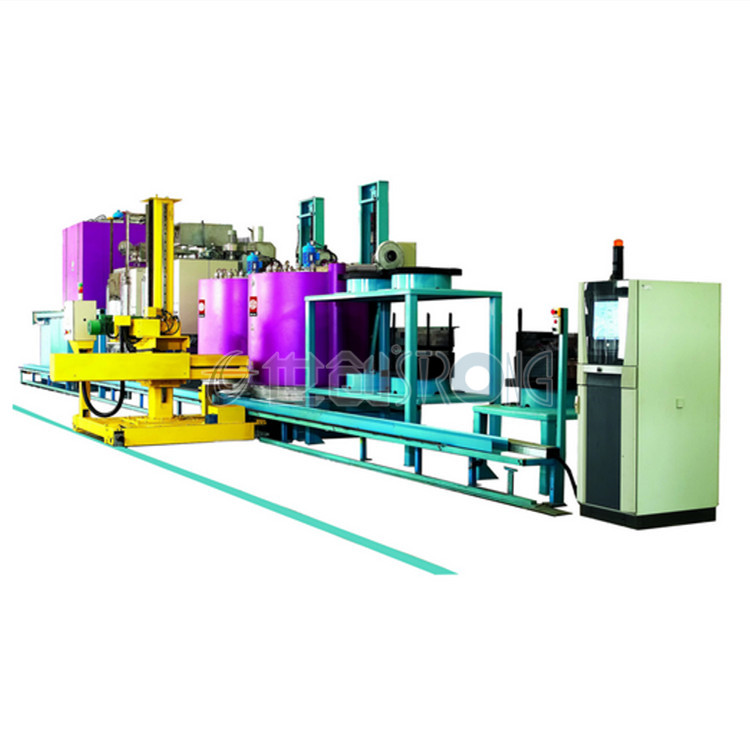

SOLO Infiltration furnace production line

Brand SOLO

Product origin CHINA

Delivery time 60

Supply capacity 100

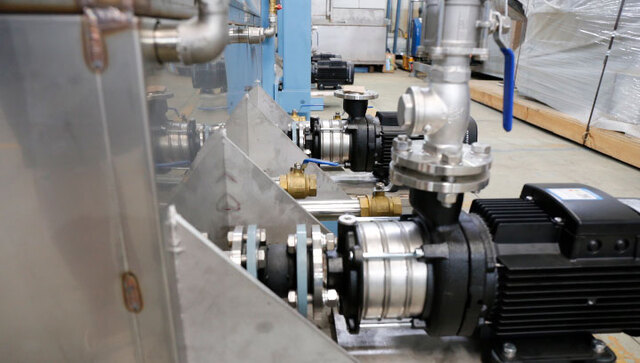

Equipment composition of the metal infiltration furnace production line: This heat treatment production line consists of 2 bottom-loading vertical multi-purpose furnaces (1100°C), 1 argon cold tank (ArB), 1 supporting loading and unloading trolley, charging table, electrical control system, It is composed of gas control system, computer control management system and circulating water cooling device.

Infiltration furnace production line

Equipment composition: This heat treatment production line consists of 2 bottom-loading vertical multi-purpose furnaces (1100°C), 1 argon cold tank (ArB), 1 supporting loading and unloading trolley, loading table, electrical control system, gas control system, It is composed of computer control management system and circulating water cooling device.

Process flow: It mainly includes the processes of loading, conveying, closing the furnace door, exhausting, heating, heat preservation, cooling, and unloading.

The furnace can be heated according to the required heating rate, which can realize the process of step heating, step cooling and cooling along with the furnace.

Equipment use:

Suitable for high temperature and medium temperature heat treatment of workpiece under protective atmosphere (argon gas):

1. Protective atmosphere (argon gas) for heating and heat preservation;

2. Cooling with the furnace or stepped cooling

3. Argon cooling;

Device parameters:

1. Effective heating zone: 400x400x700H;

2. Maximum loading capacity: 150kg;

3. The highest temperature: 1150℃;

4. Instrument recording accuracy: ±1℃;

5. Furnace temperature uniformity: ≤±5℃;

6. Quenching transfer time: ≤15s