-

10-20 2021

Various heat treatment methods for carburizing and carbonitriding gears

Various heat treatment methods for carburizing and carbonitriding gears

-

10-16 2021

Heat treatment of bearing steel - strong metal heat treatment furnace

Bearing steel ingots are generally subjected to long-term diffusion annealing at a high temperature of 1200 ~ 1250 ℃ to improve carbide segregation. The atmosphere in the furnace should be controlled during hot working, the heating temperature of the billet should not be too high, and the holding time should not be too long to avoid serious decarburization. The final rolling (forging) temperature is usually between 800 and 900 ℃. If it is too high, it is easy to appear coarse network carbides, and if it is too low, it is easy to form rolling (forging) cracks. The finished rolled (forged) material should be quickly cooled to 650°C to prevent cementite from precipitating in a network on the grain boundary. If conditions permit, a controlled rolling process can be used.

-

09-24 2021

Defect Analysis and Repair of Bright Annealing Muffle Furnace for Stainless Steel Strip

The stainless steel bright annealing production line (BAL) of a steel mill is a large-scale production line designed and manufactured by a foreign company for bright annealing stainless steel strips. Its total height is 55m, and it can handle stainless steel plates with a width of 600 to 1250 mm and a thickness of 0.1 to 3.0 mm. belt.

-

08-17 2021

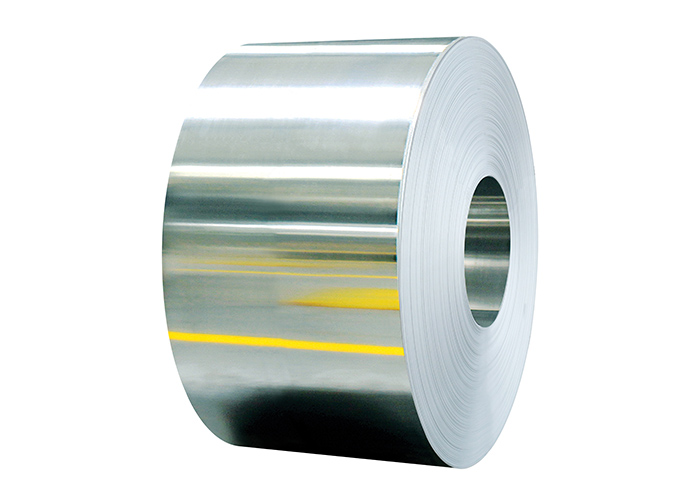

The key delivery finishes of stainless steel coil or strip or sheet

what are the differences among 2E, 2D, 2B and BA?

-

08-14 2021

Heat treatment of cold worked stainless steel strip

In most cases of cold rolled stainless steel strip, annealing process is needed to achieve appropriate mechanical properties by continuous bright annealing furnace.

-

08-04 2021

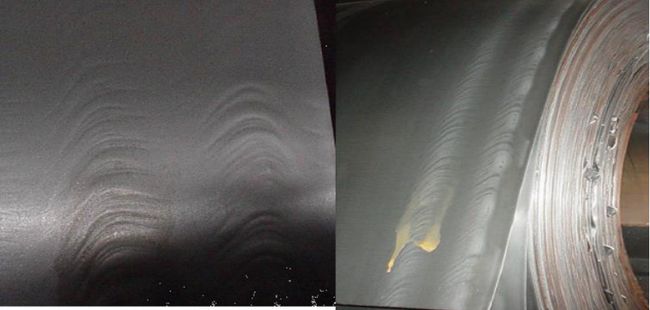

Main defects of bright annealed strips

the post covers main deffects of bright annealed strips by bright annealing furnace.